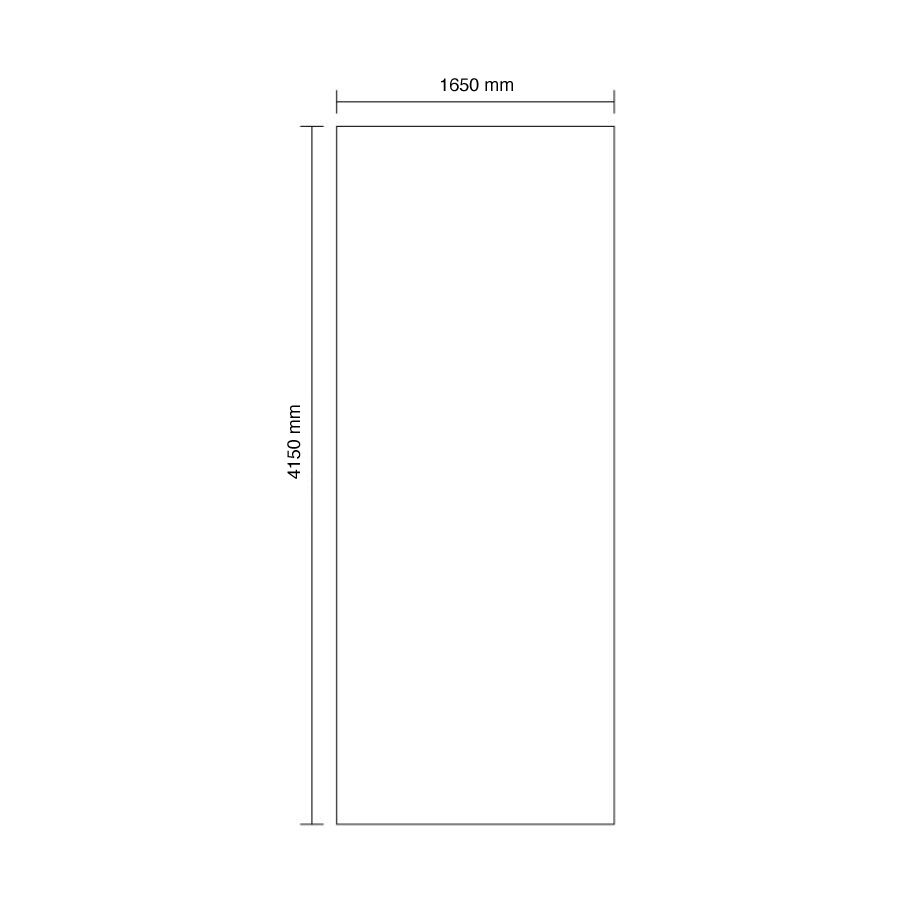

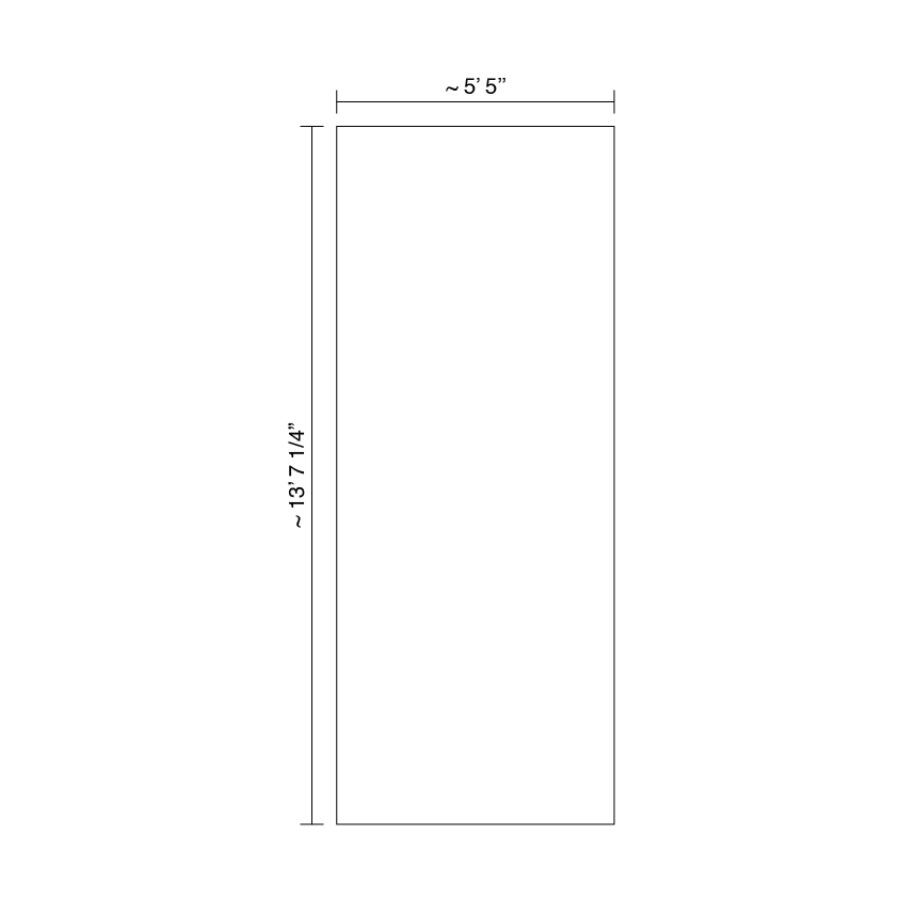

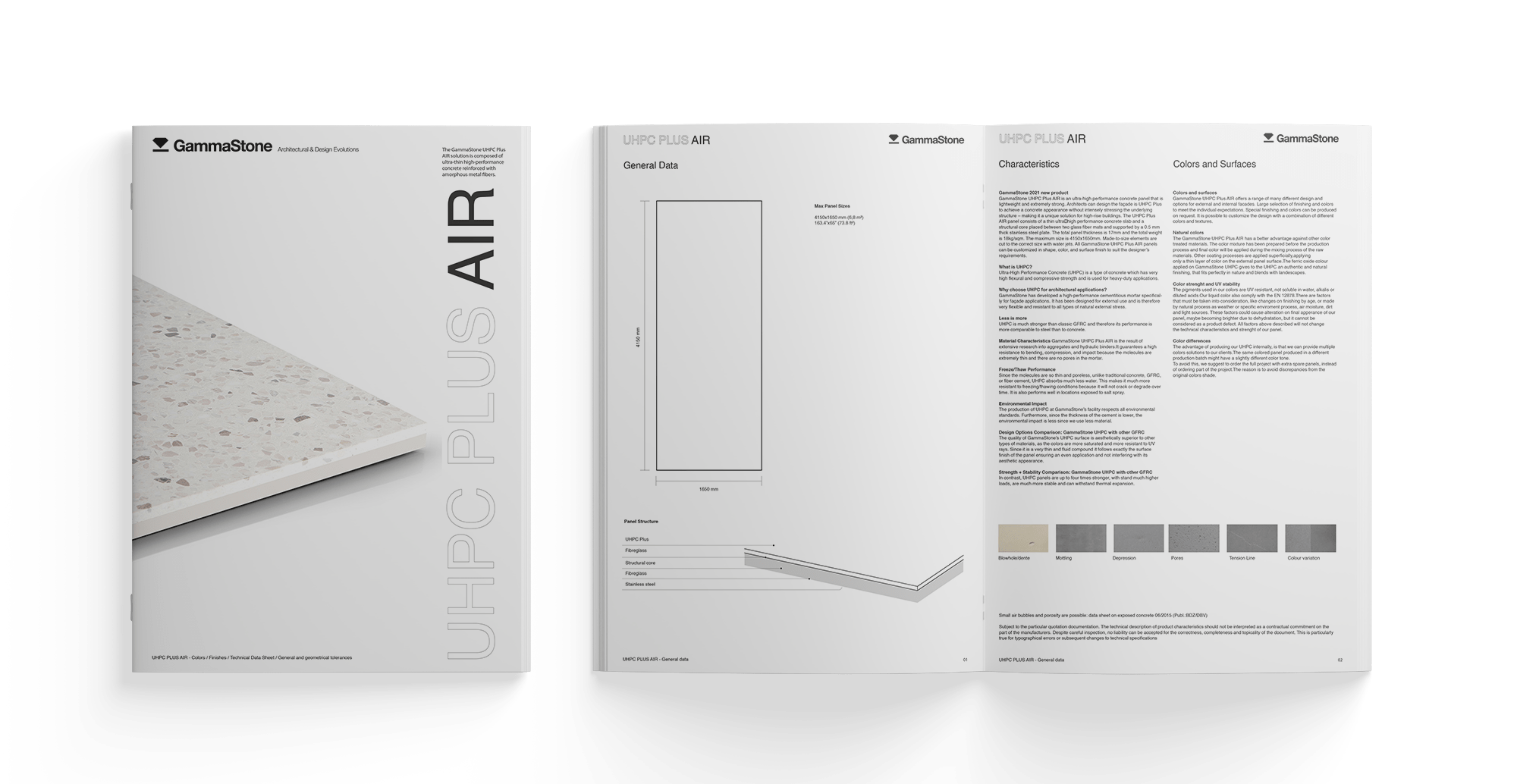

Max Panel Size

4150×1650 mm

Weight

24 kg/m2

Panel Thickness

19 mm

UHPC Thickness

8 mm

Finishes

3 treatments

Colors

48 + others on request

GammaStone UHPC Plus Air: the lightweight and resistant panel

The Ultra-High Performance Concrete panel consists of a thin reinforced concrete sheet with fiberglass and a structural core placed between two layers of fiberglass mats, supported by a 0.5 mm thick stainless steel plate.

UHPC exhibits extremely high strength while maintaining exceptional flexibility. The cement mortar we have developed is highly performant and specifically designed for facade applications. Its molecules are extremely thin, allowing it to absorb less water during the freeze/thaw phase, preventing cracks and degradation, even in locations exposed to salt spray.

GammaStone UHPC is up to four times stronger than traditional GFRC and can withstand higher loads, with performance comparable to steel. The colors are more saturated and UV rays resistant, making it aesthetically more appealing than other materials.

Our production of UHPC panels respects all ecological parameters. Furthermore, the low thickness of the cement allows us to have a lower environmental impact compared to solutions that use a larger quantity of material.

Large Format

The patented GammaStone Air panels are produced by cutting-edge automated 4.0 systems that allow them to be created in large format.

Thanks to our experts, we are able to create extremely light coatings with very high resistance to impacts, bending and compression.

Our panels are made with innovative materials used in the aerospace industry and can reach 4150×1650mm in the UHPC version.

Reserved for Architects

At GammaStone we have the ability to make each project unique, even by choosing UHPC as a solution.

Being able to count on decades of experience in the use of these materials, we are certain of guaranteeing a very high quality service.

Our goal has always been to best enhance the originality of each project.

Infinite customization

Our UHPC is manufactured in GammaStone’s in-house facilities and can be customized according to the specific request of the architect.

We use high quality oxides and grits, available in all shades of color, making the color palette infinite.

These components can be mixed together to obtain any shade, creating a completely customized material with a unique finish, designed and produced exclusively for the project itself.

Sand

Cement

Water

Glass fiber

The Composition of UHPC

UHPC Plus Air is an ultra-high performance concrete optimized specifically for building enclosures. Ultra-High Performance Concrete (UHPC) is a cementitious material with a densely packed particle matrix designed for longevity. The result is an extremely durable concrete without the voids or environmental vulnerabilities common in traditional concrete. GammaStone takes the proven UHPC technology and increases its performance, resilience and design features for large-scale building facades.

Self-cleaning technology

The self-cleaning technology of our UHPC is an innovative approach that uses light to clean and purify our panels. With GammaStone's UHPC coatings we can have buildings with a cleaner and clearer appearance by effectively breaking down dirt and organic residues that settle on the surface.

Our technology provides a sustainable and environmentally friendly solution, as it uses natural processes and does not rely on chemicals or consumable materials Furthermore, it helps reduce maintenance efforts and associated cleaning costs, as the self-cleaning properties minimize the need for manual intervention.

Finally, its ability to mimic the self-cleaning properties found in nature offers a solution for maintaining cleanliness, improving air quality and promoting sustainability in different applications.

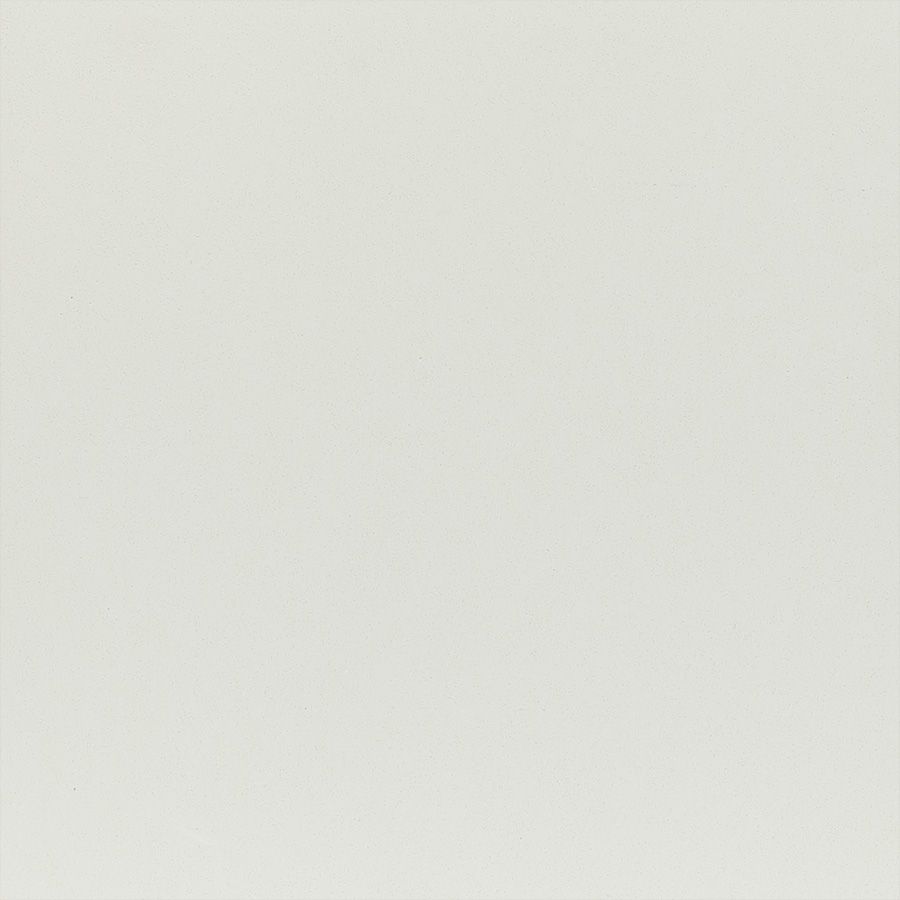

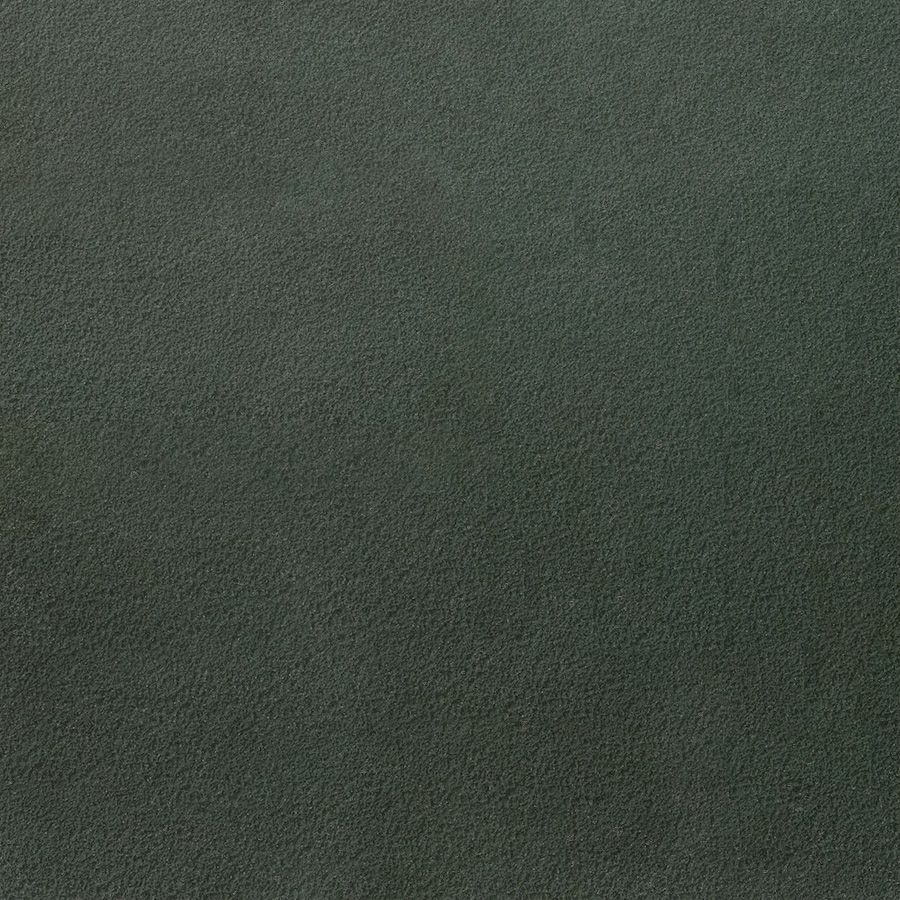

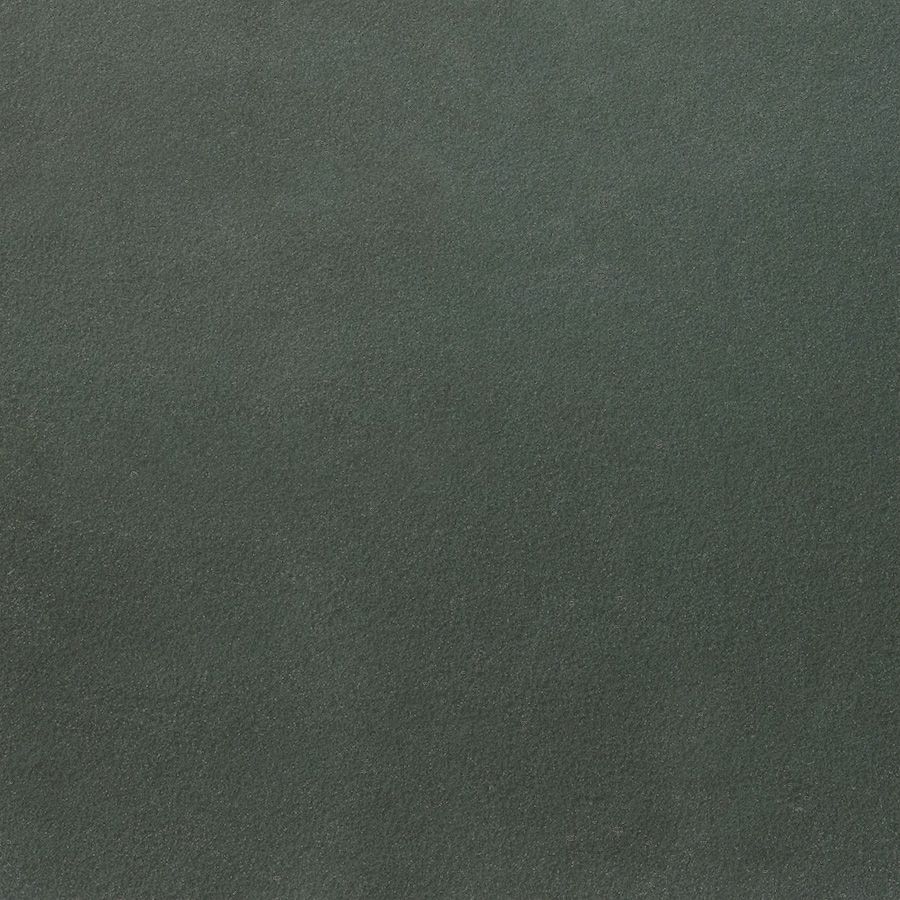

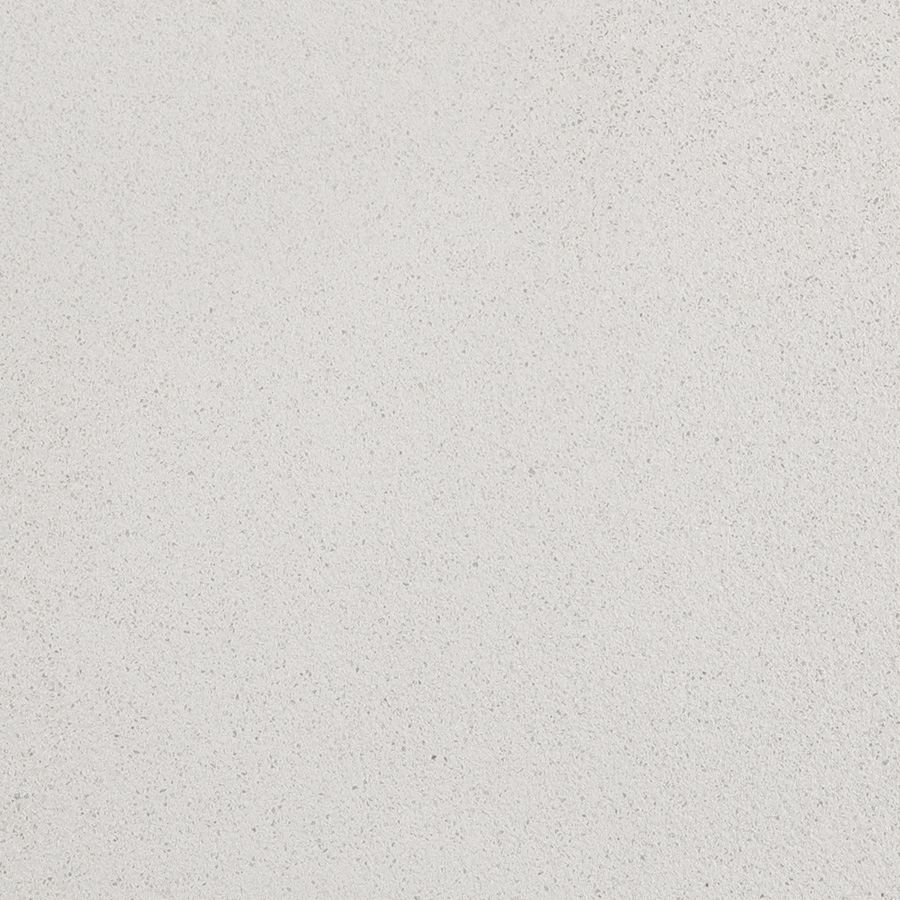

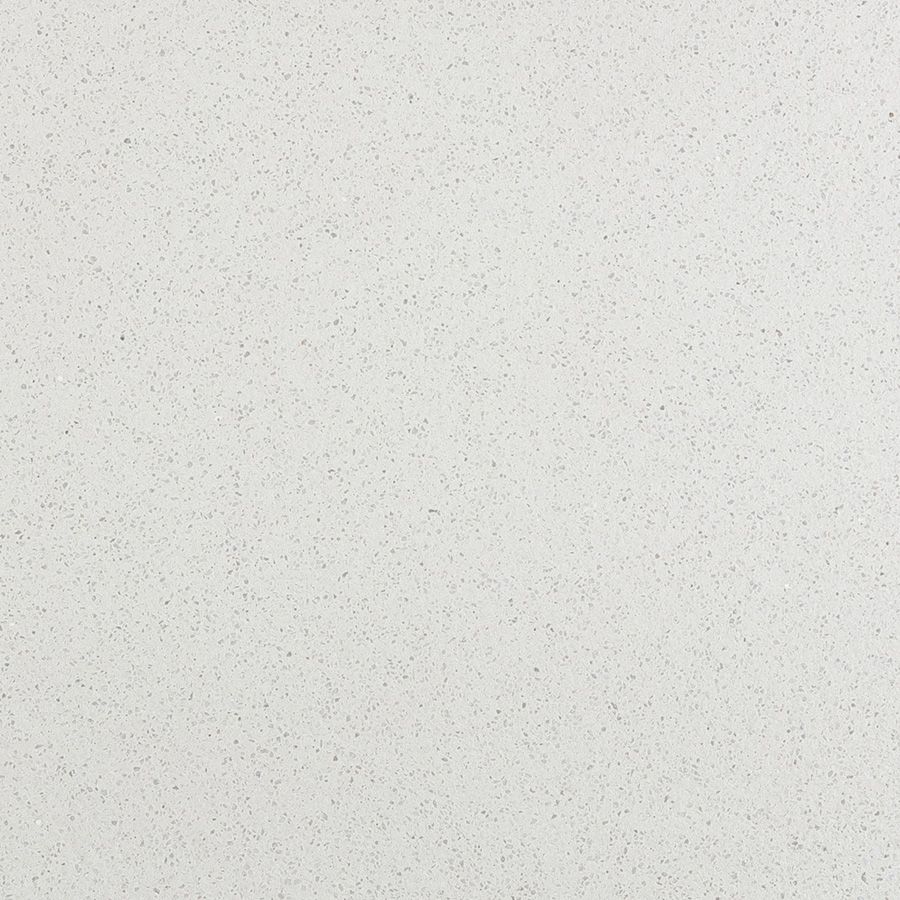

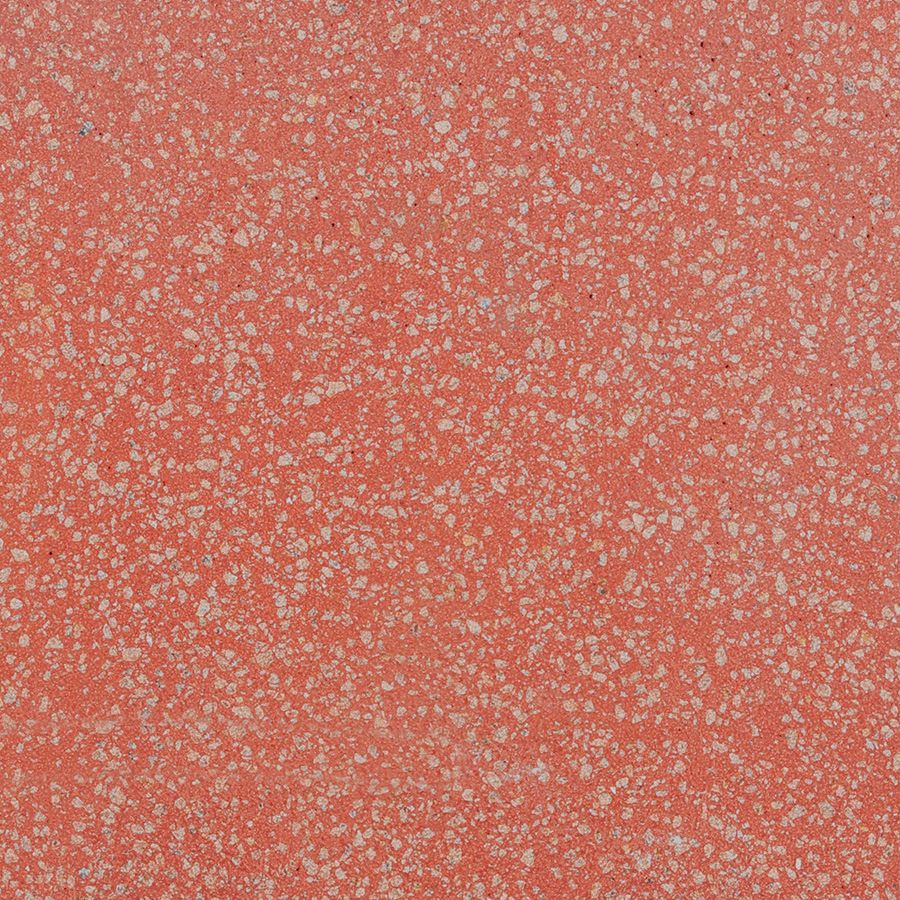

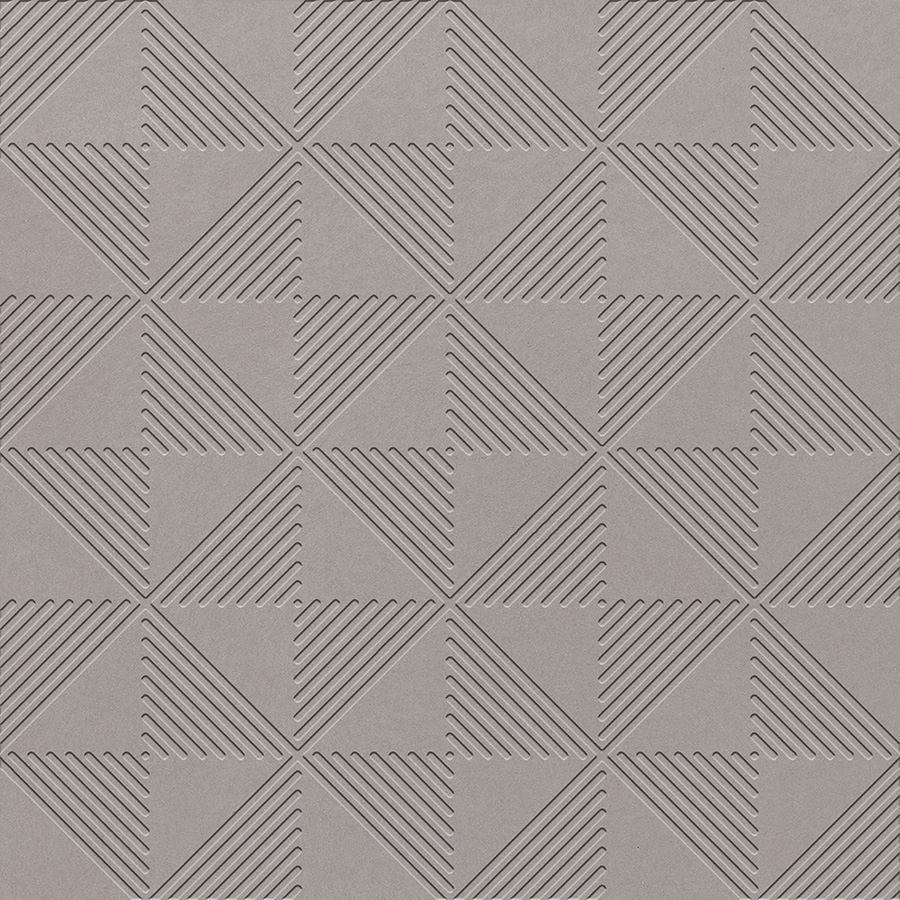

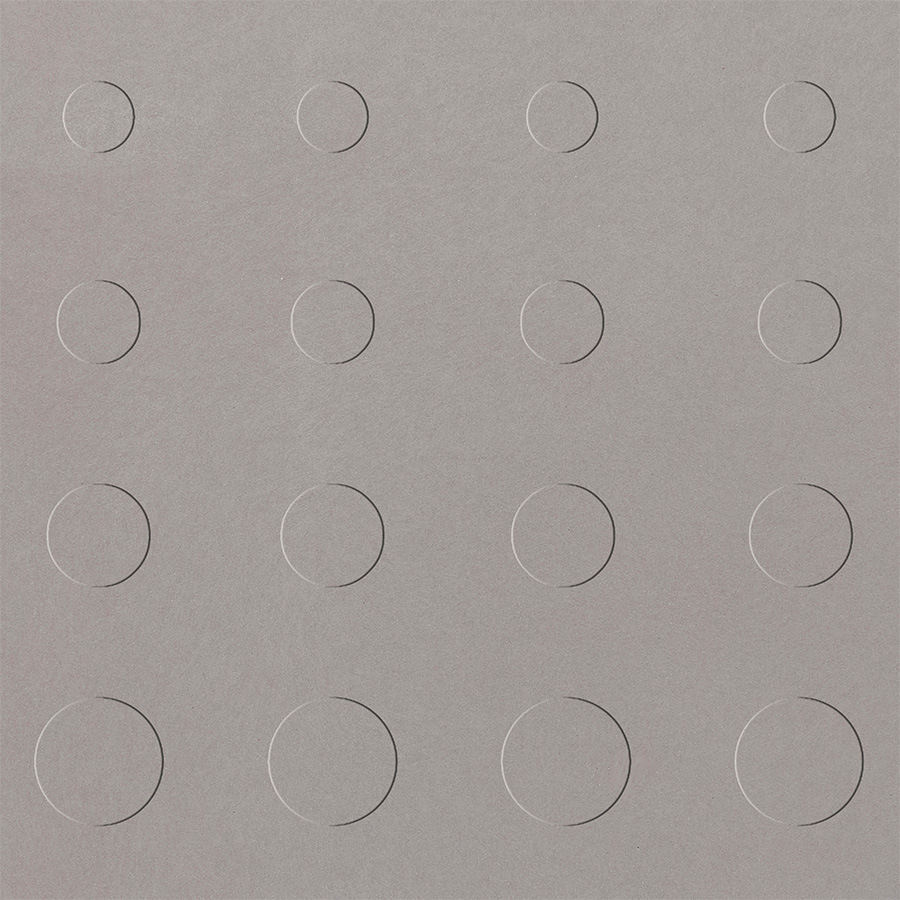

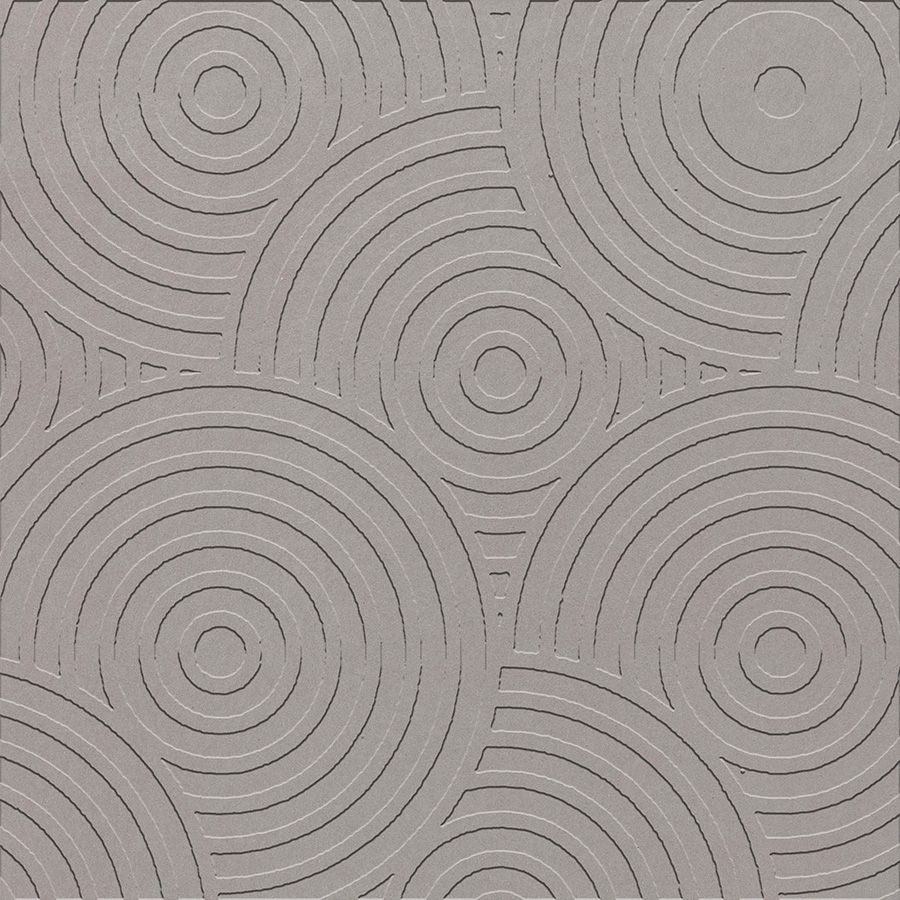

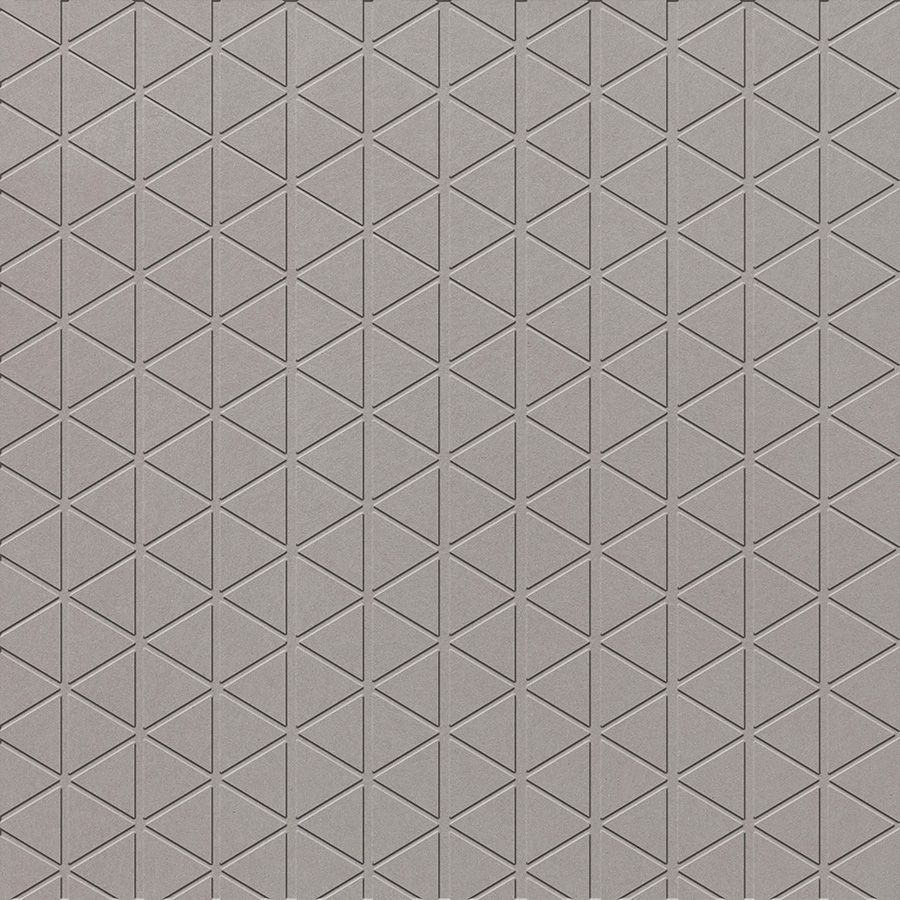

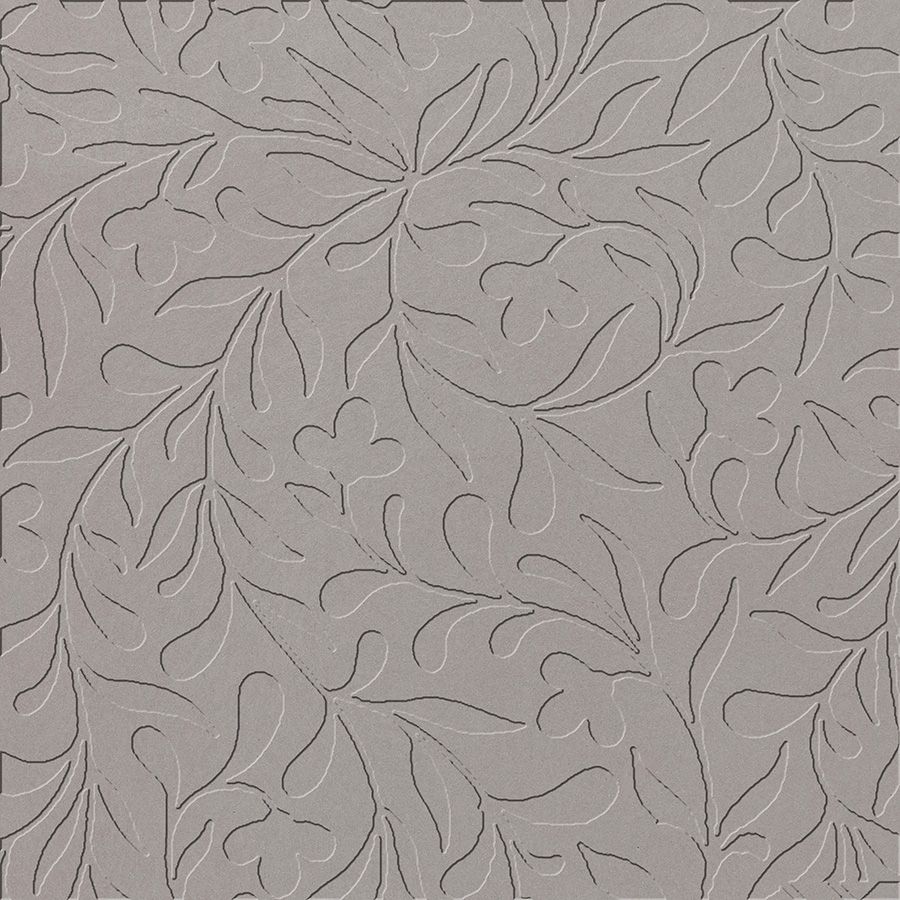

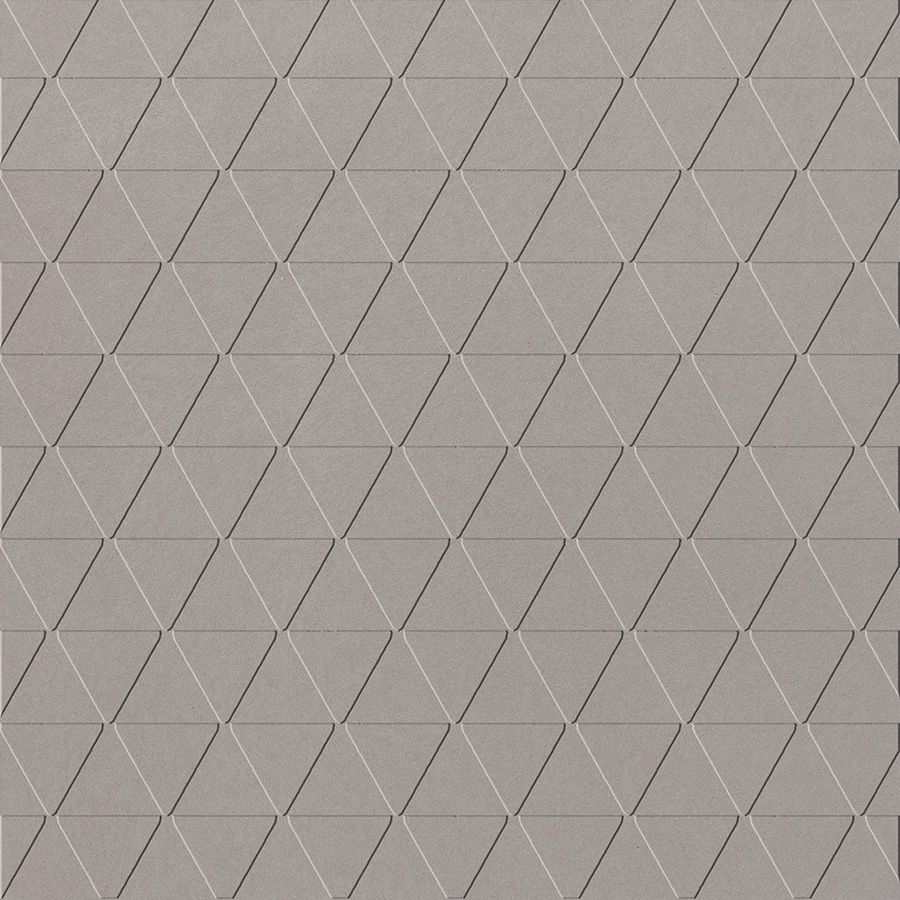

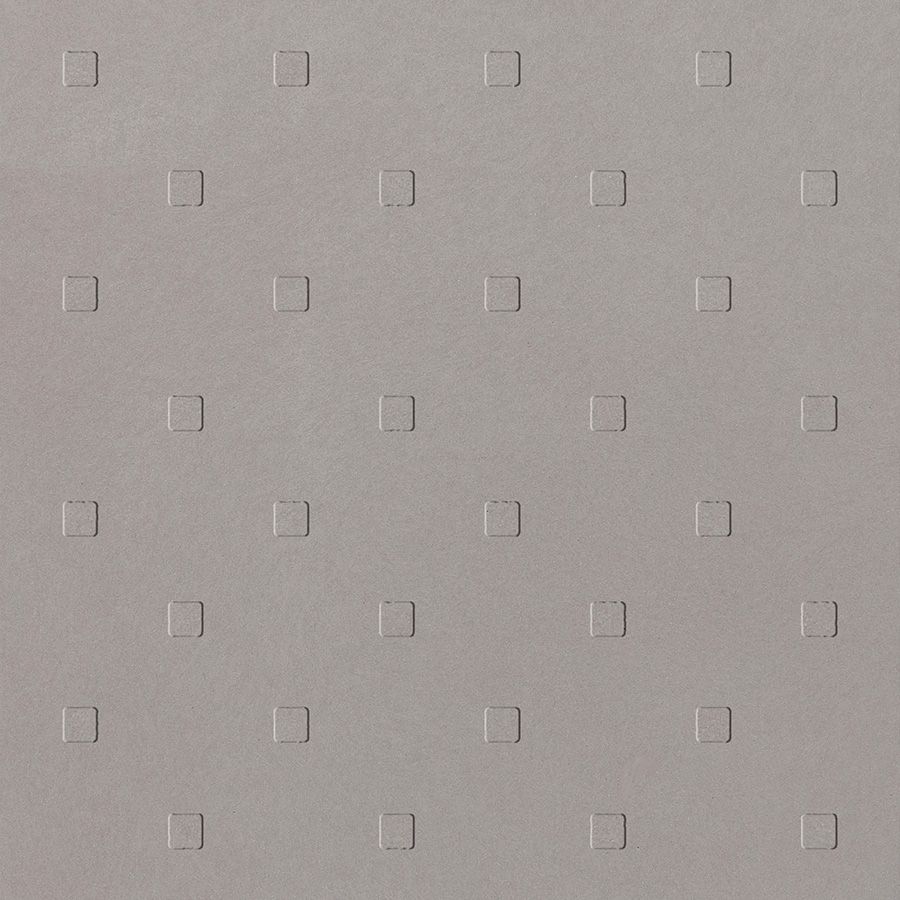

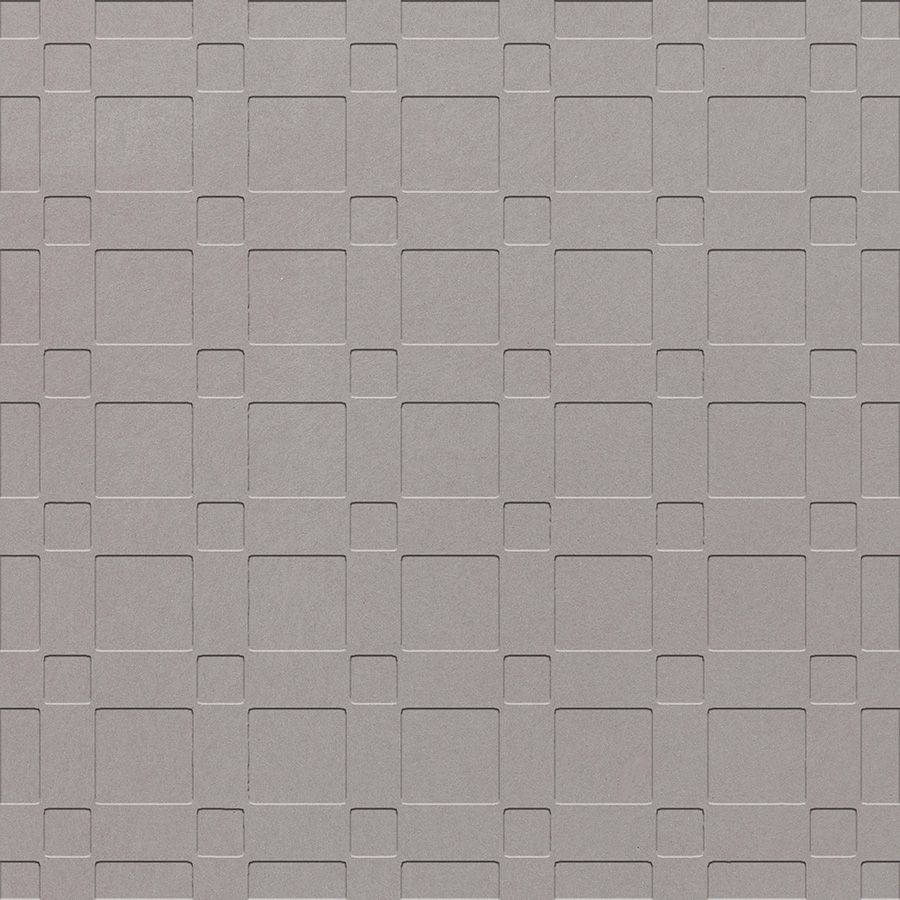

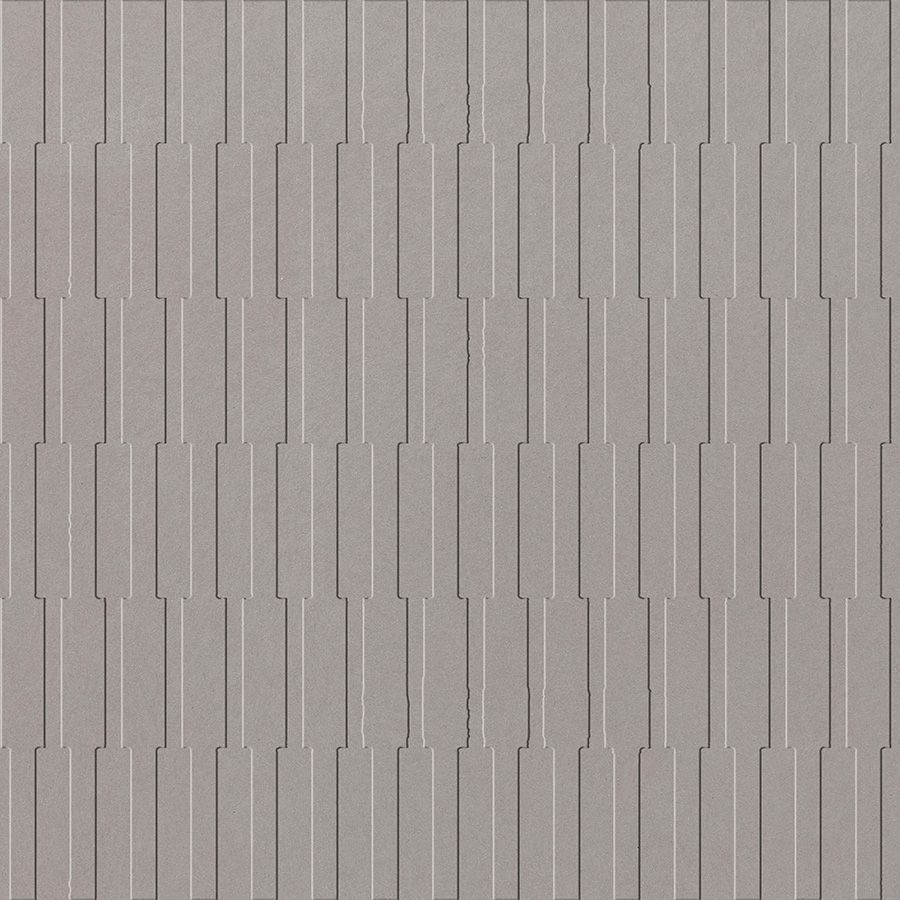

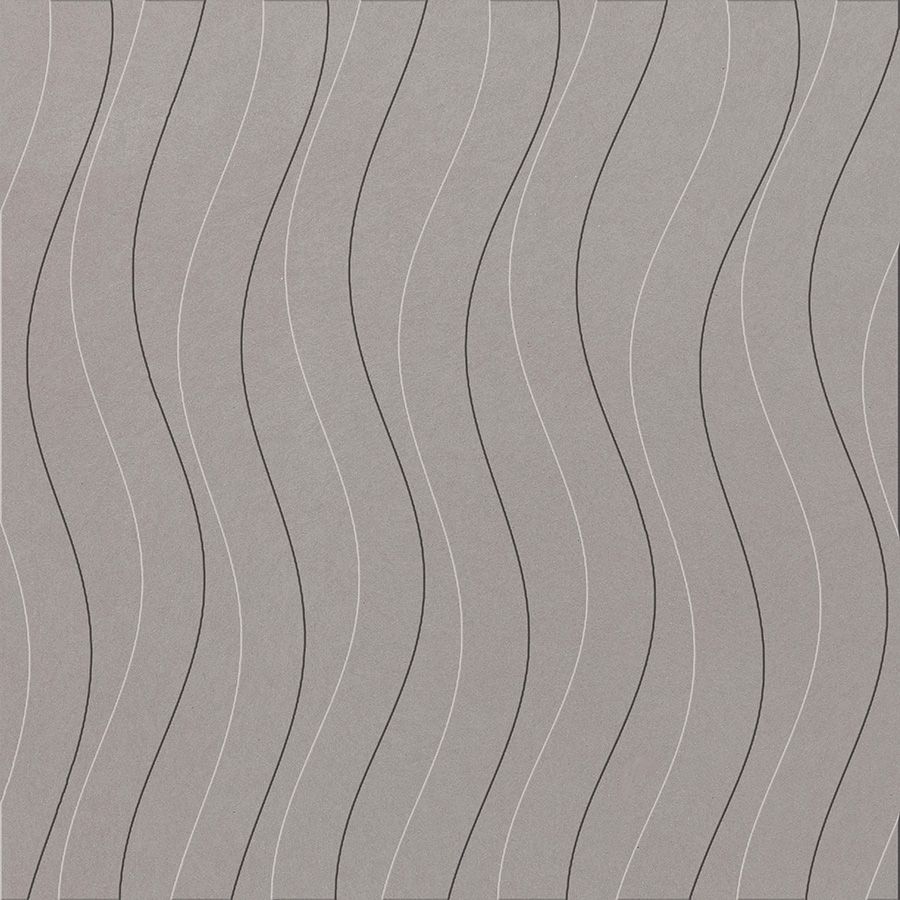

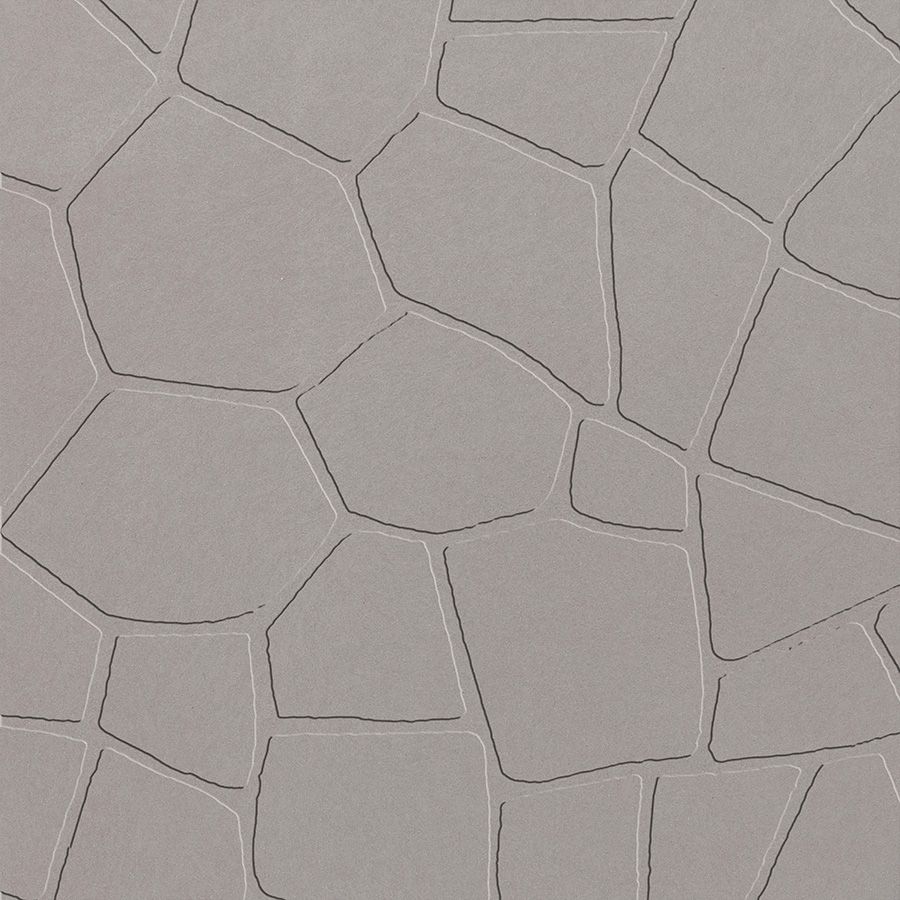

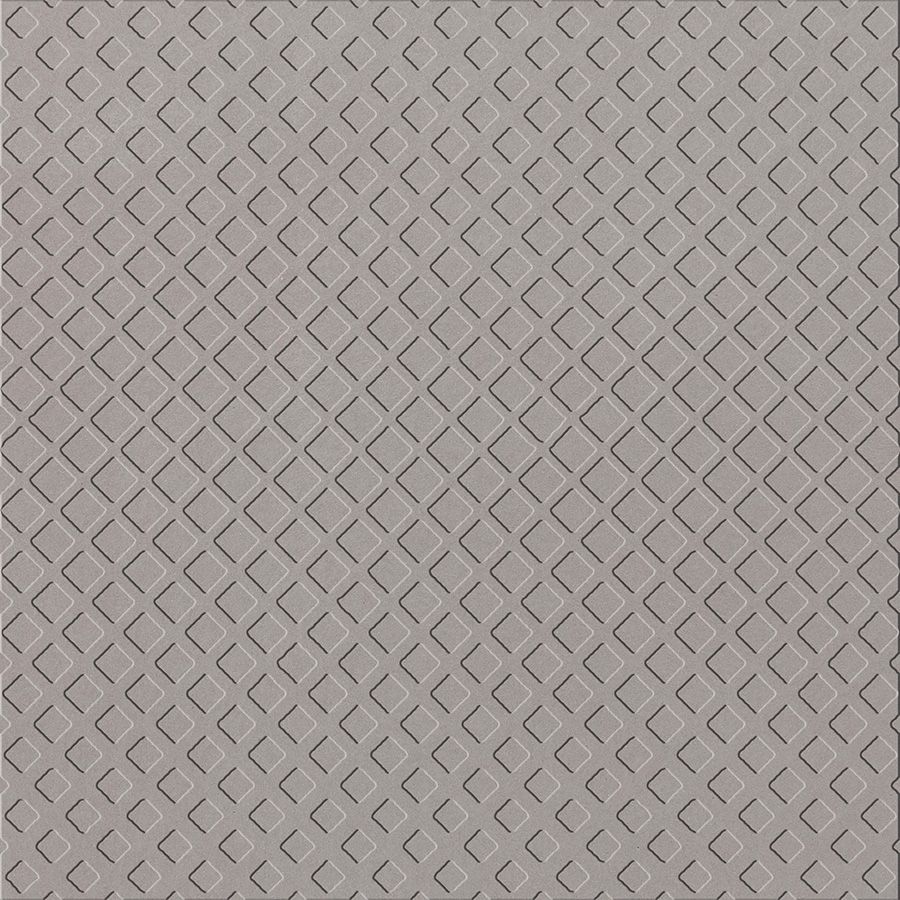

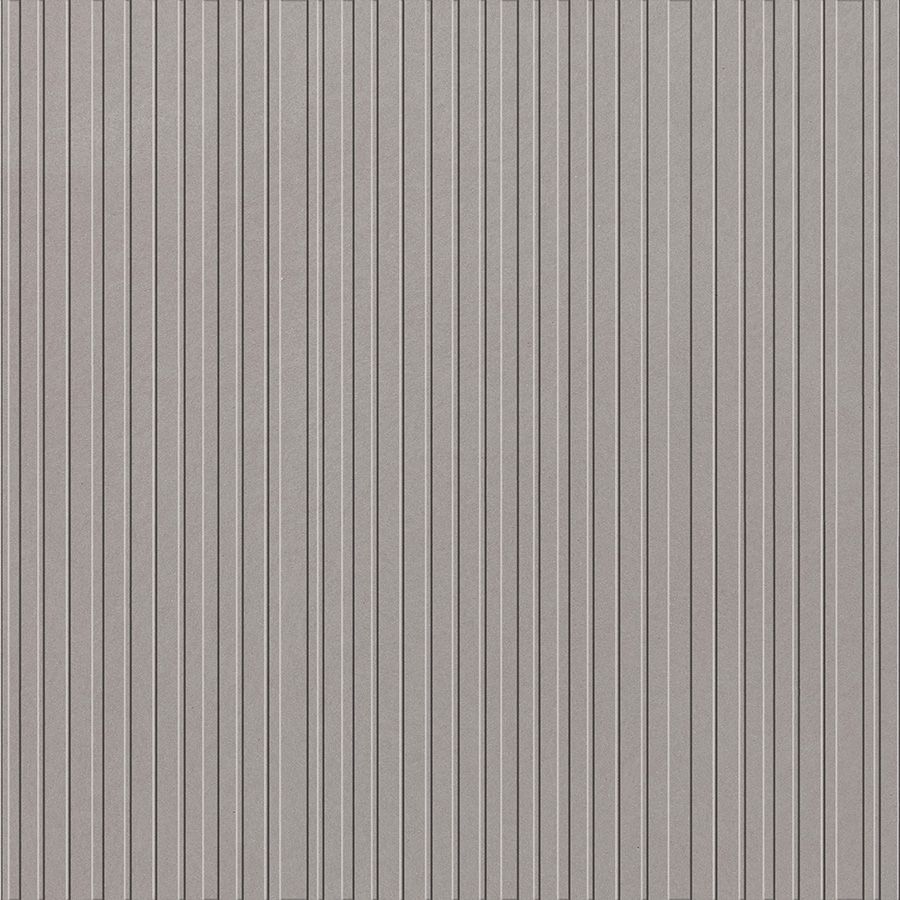

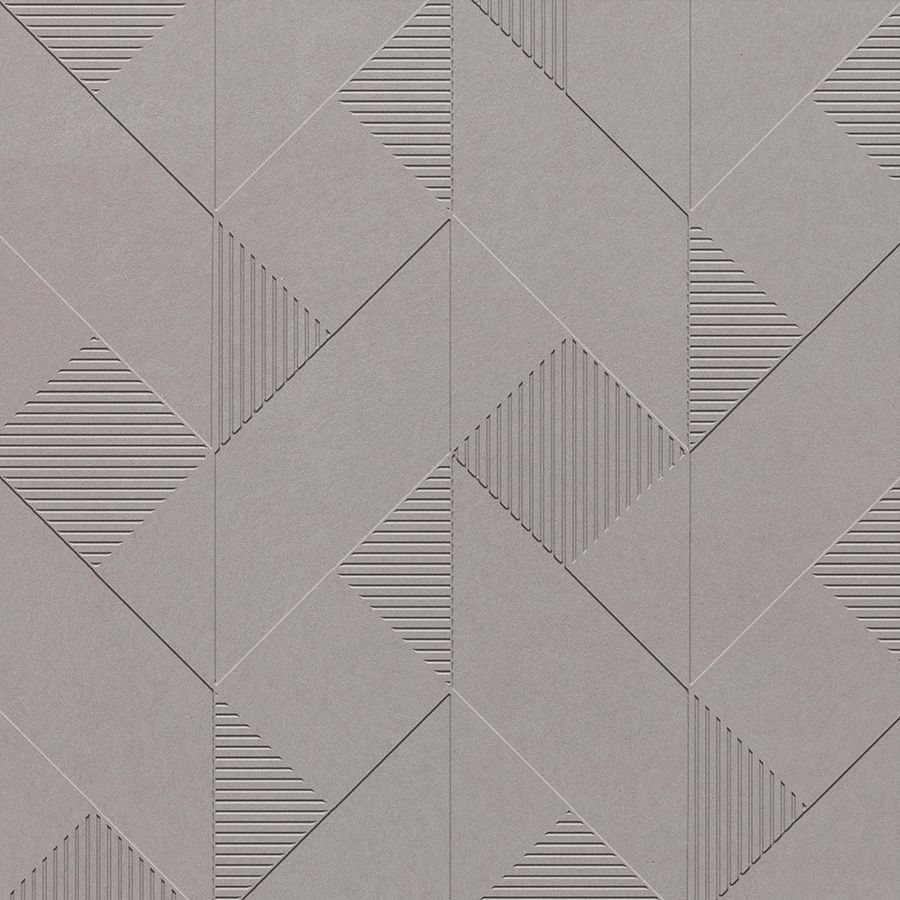

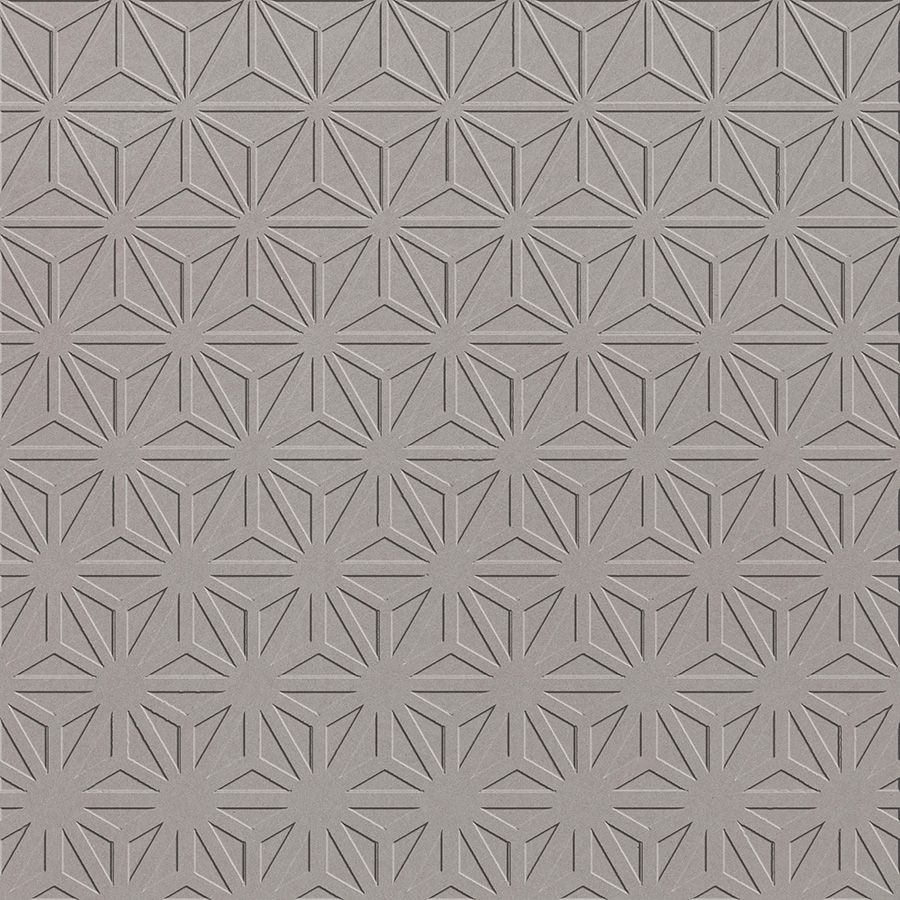

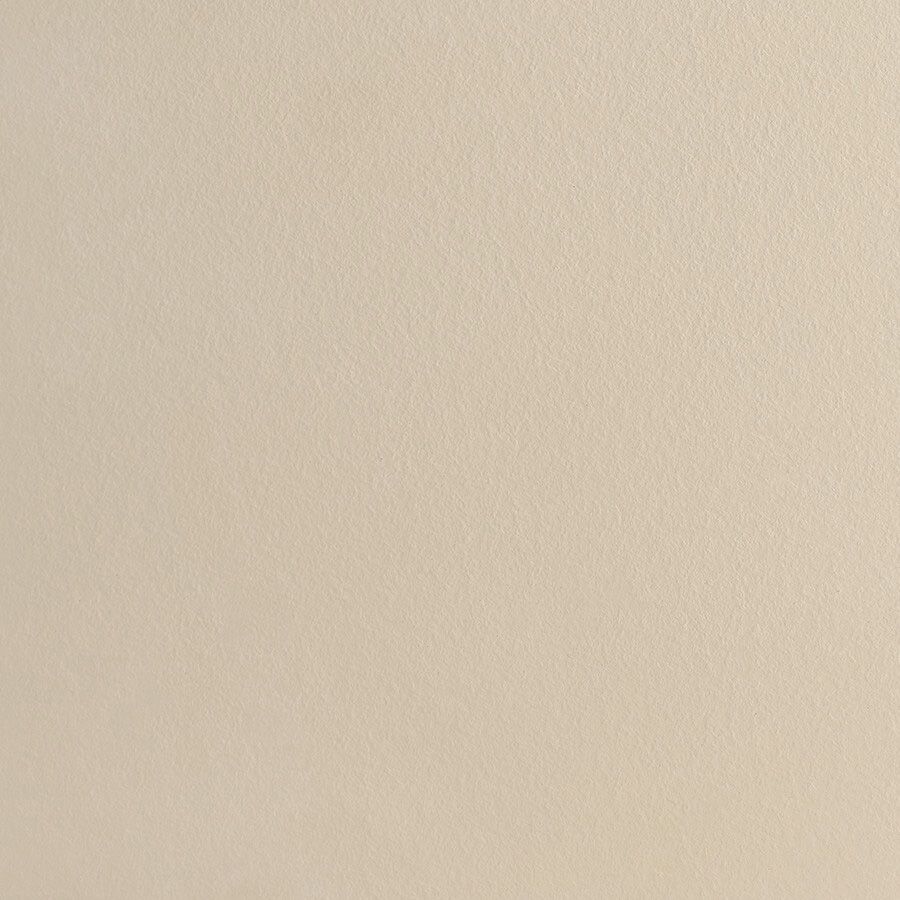

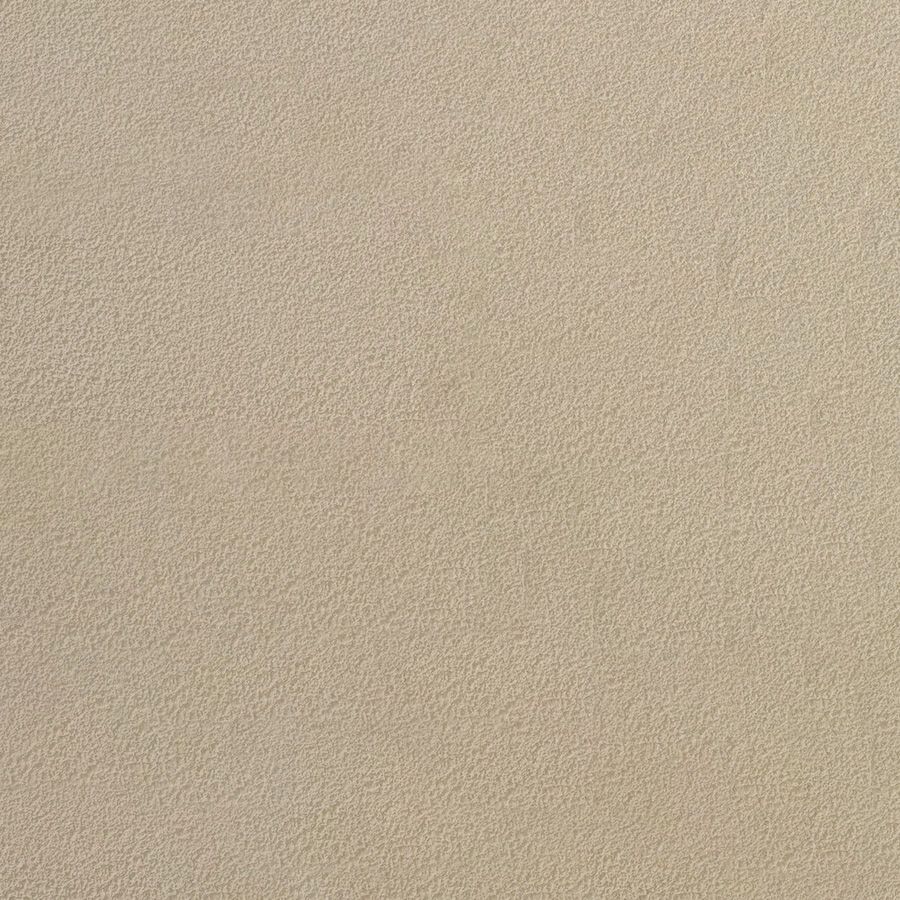

PLAIN

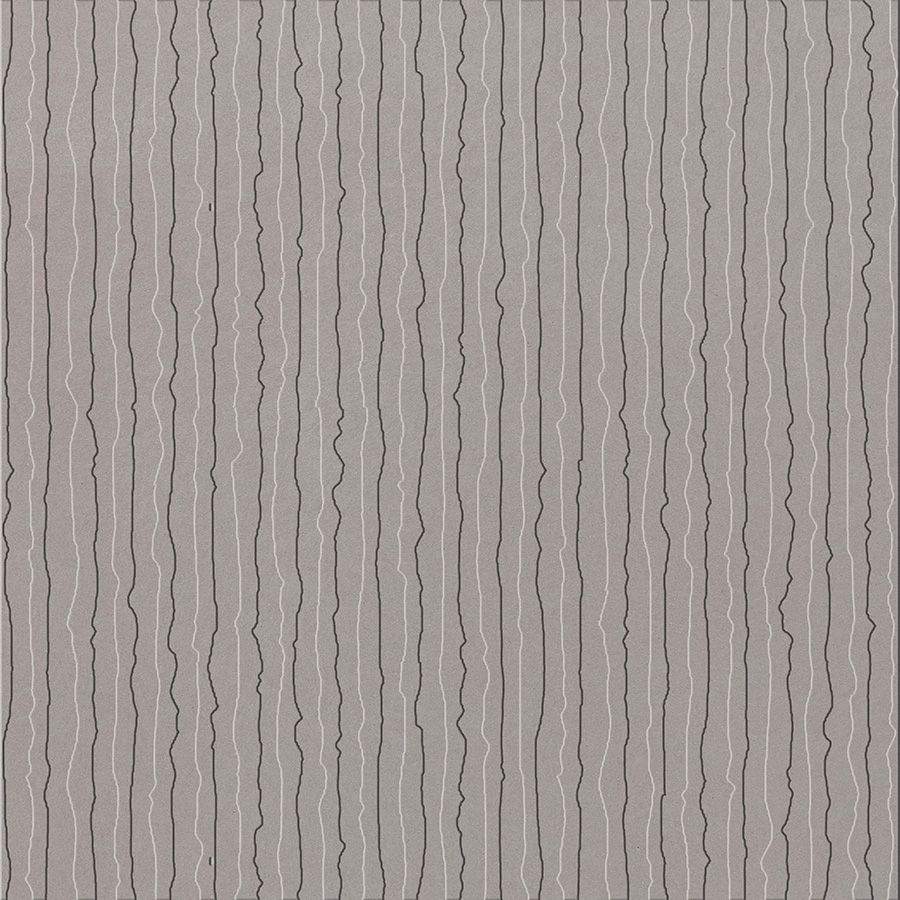

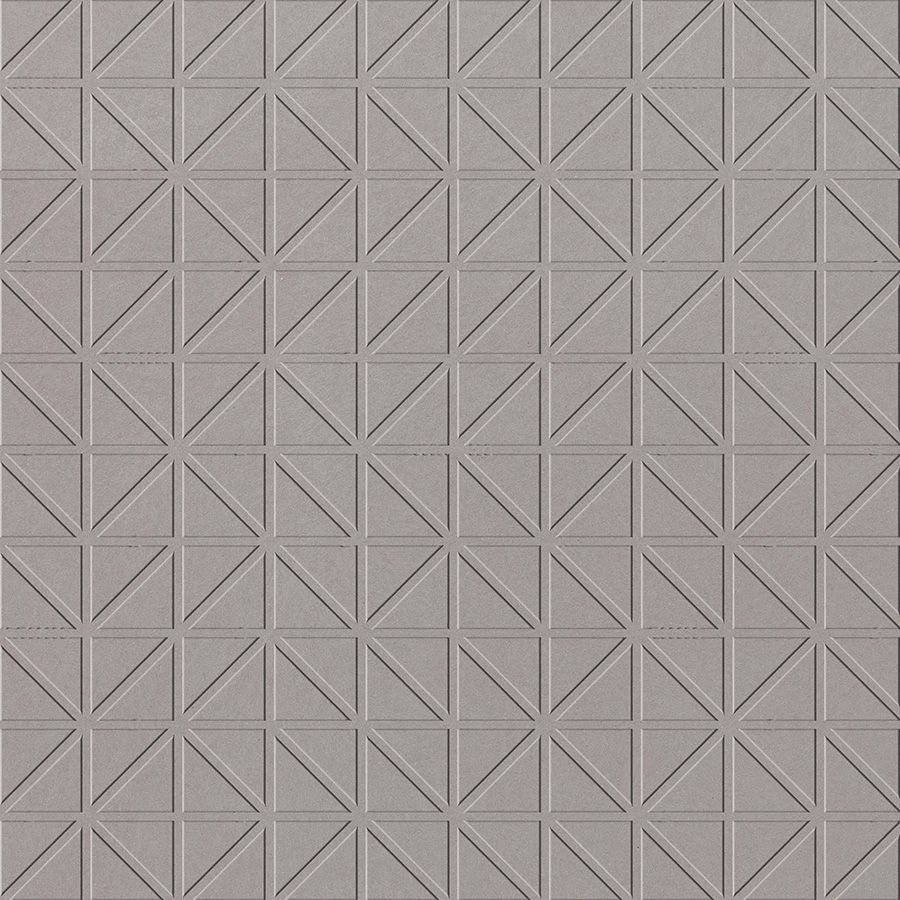

UHPC PLAIN is created using high quality oxides available in all shades of colors. These oxides can be mixed together to achieve any shade, much like working with watercolor paints. In the same way, the structure can be tailored to meet any requirement, as the surface, thanks to a functional exact copy matrix system, is capable ofoeproducing and adopting the characteristics of all the textures and can even be applied to a custom-made 3D design.

UHPC is an extremely versatile material, which can be extruded onto different matrices and has the ability to take on any pattern or texture. It is an eclectic surface that can alter its physical qualities not only visually. This feature makes it the ideal solution to meet the creative needs of any project.

We have created a selection of 24 PLAIN color options to which one of the three available finishes can be applied.

Honed

Bush-Hammered

Bush-Hammered Brushed

Colors

Finishes

Colors

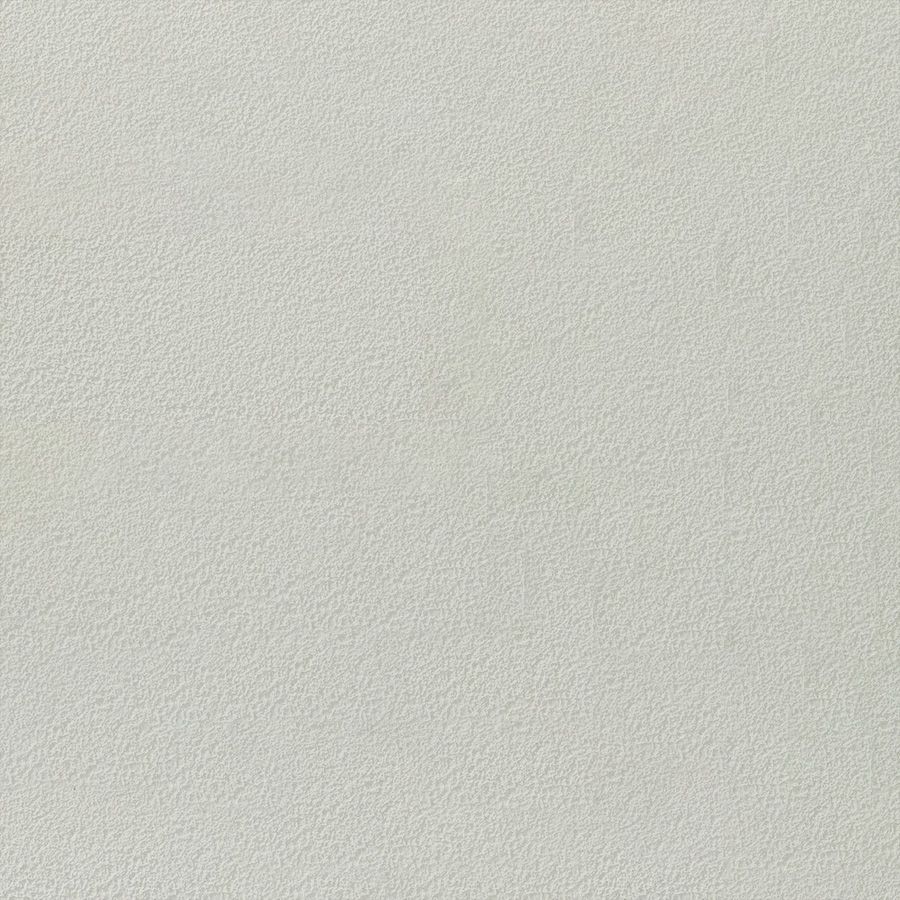

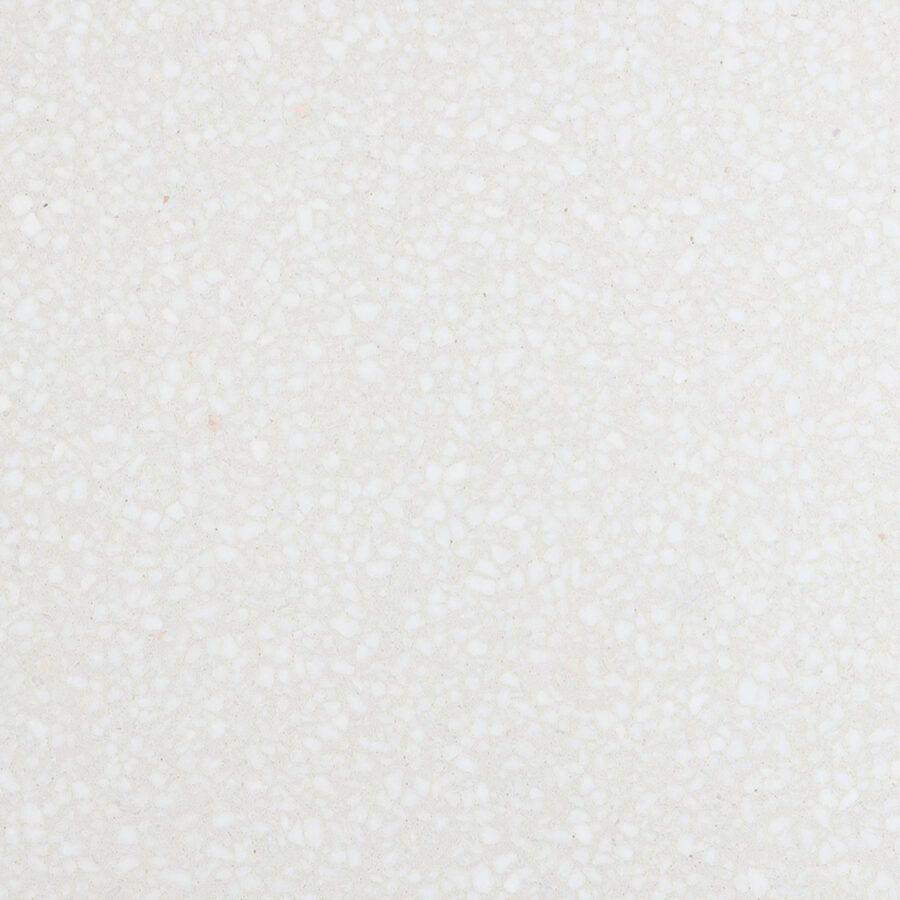

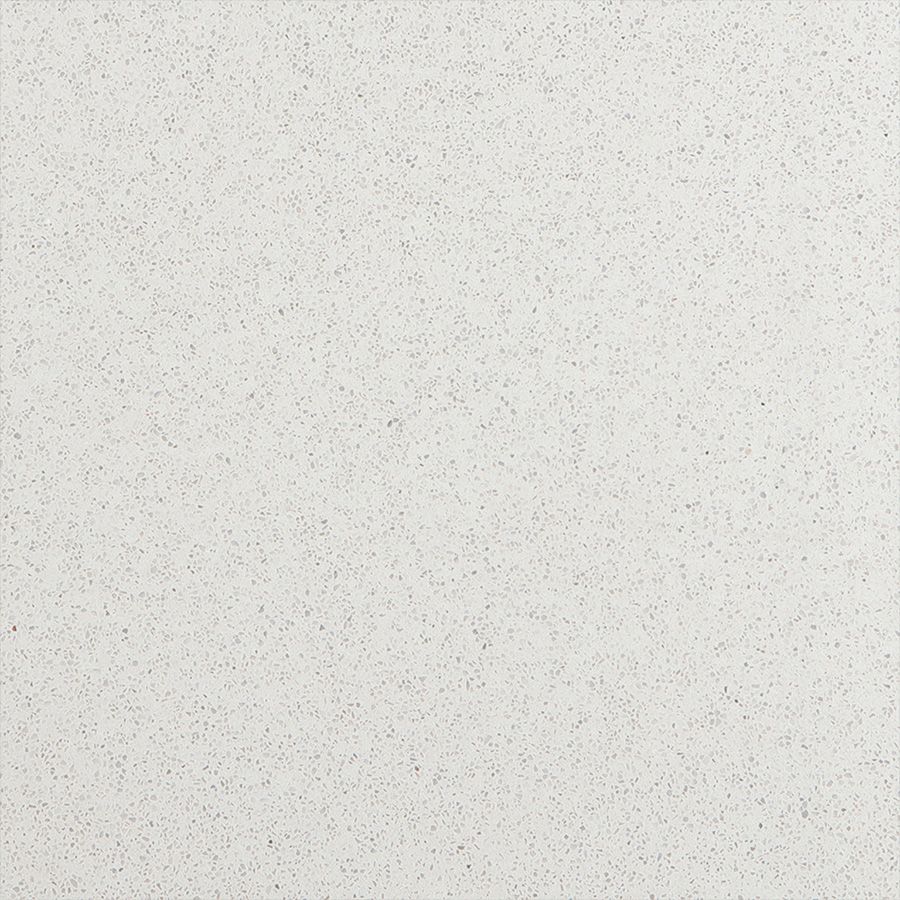

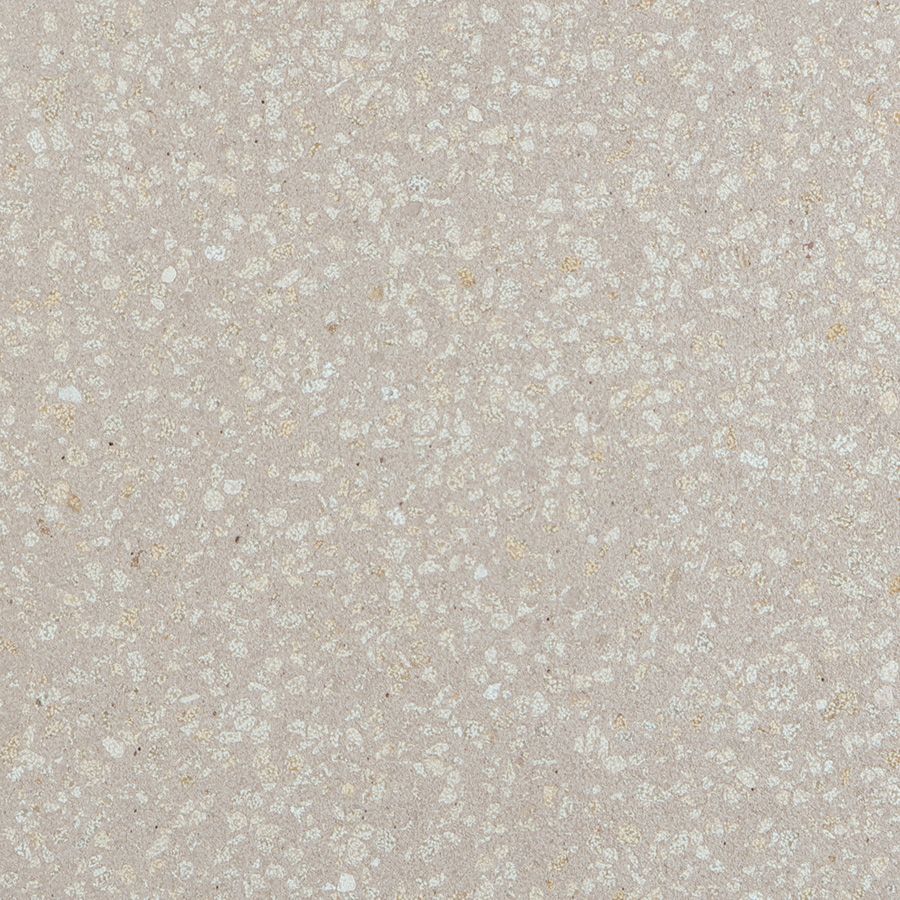

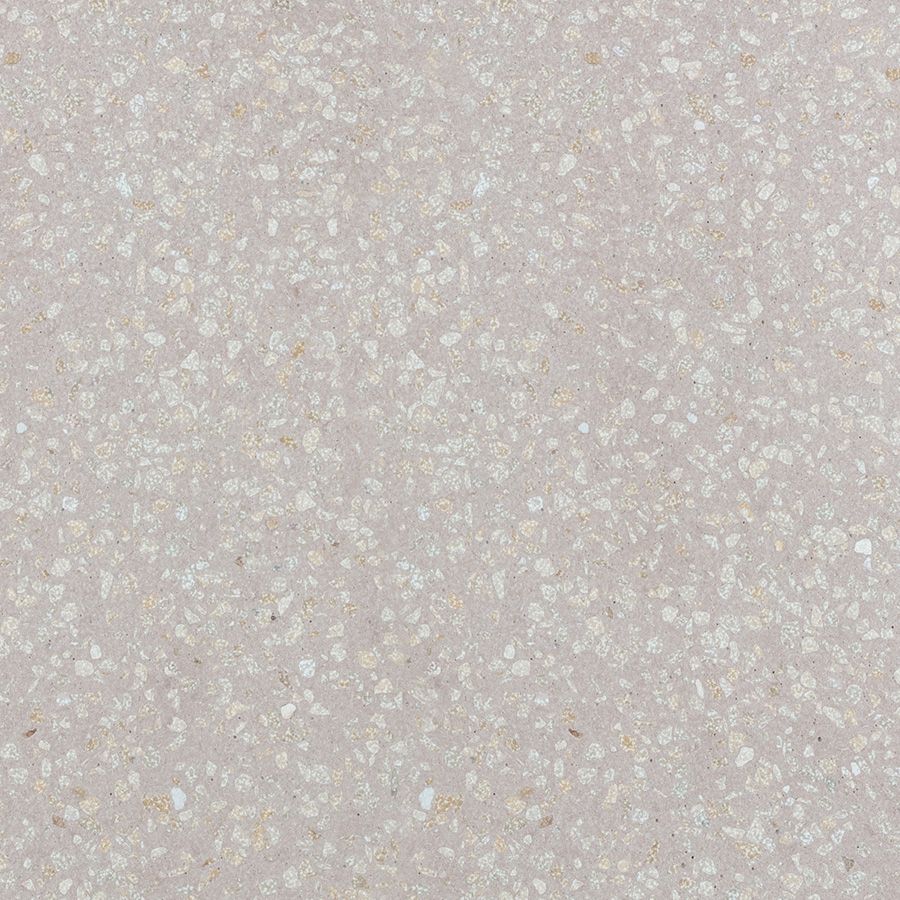

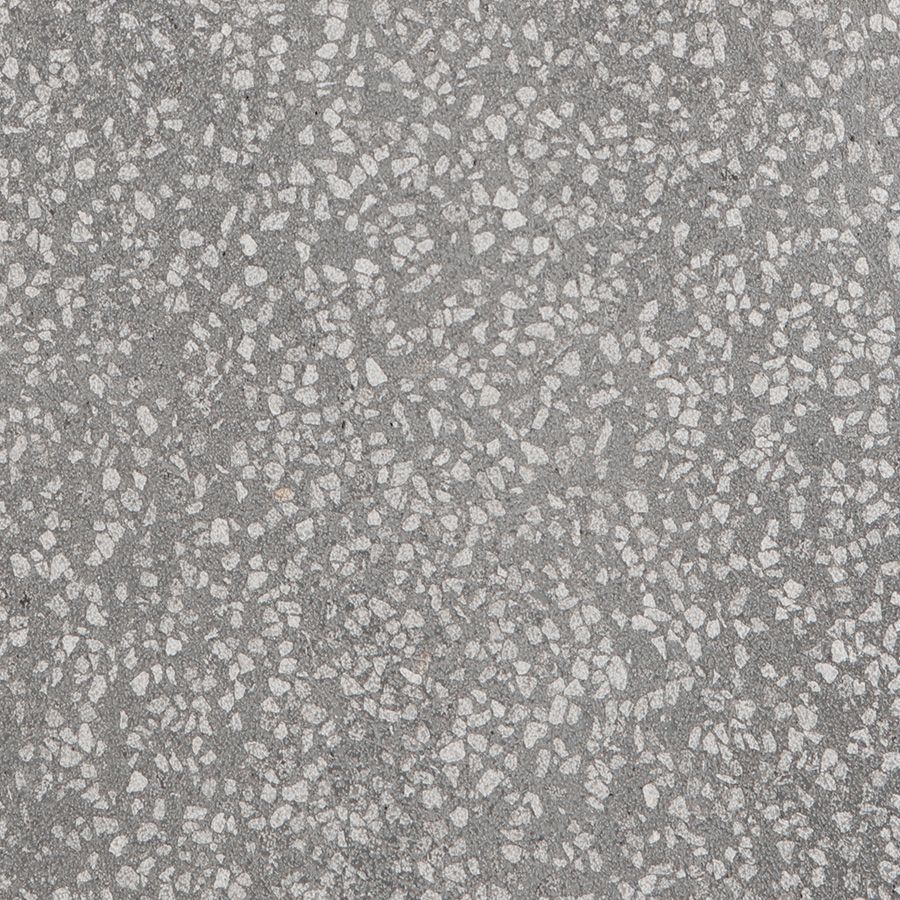

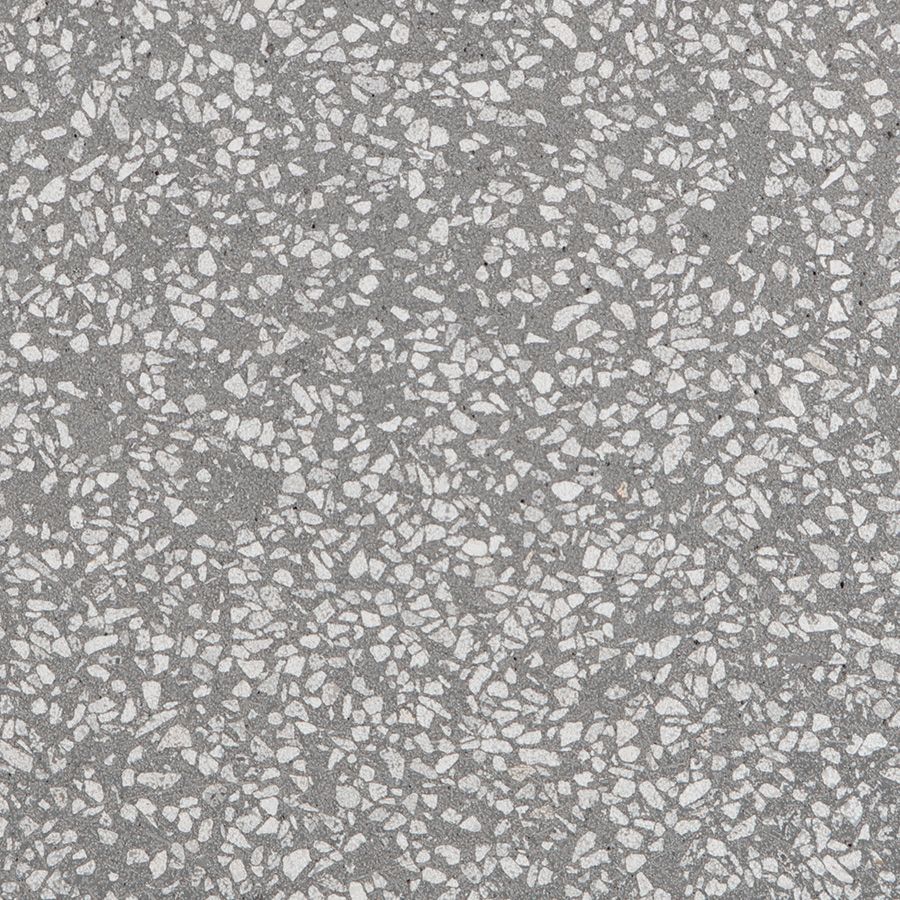

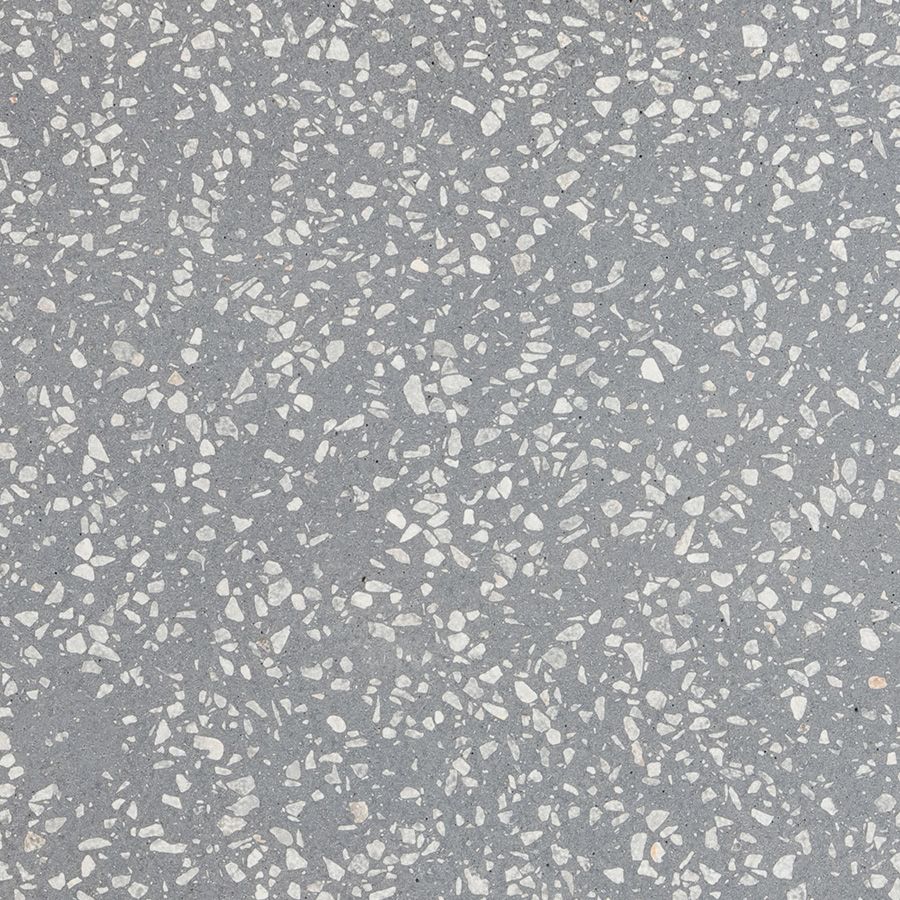

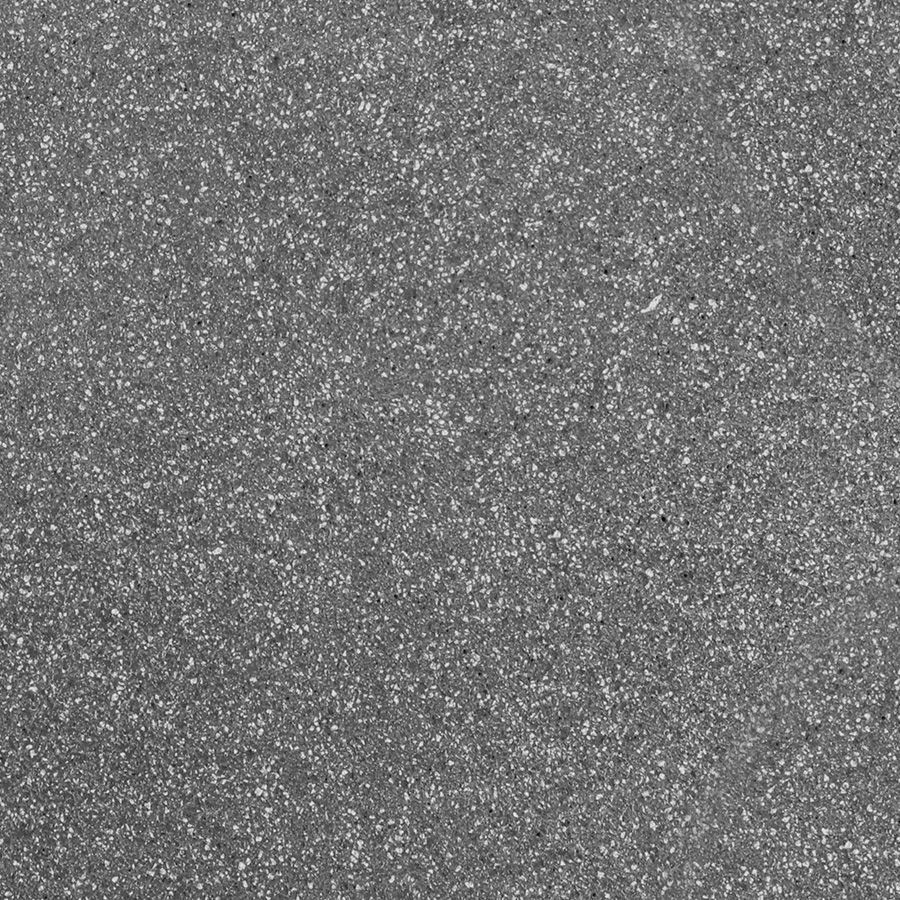

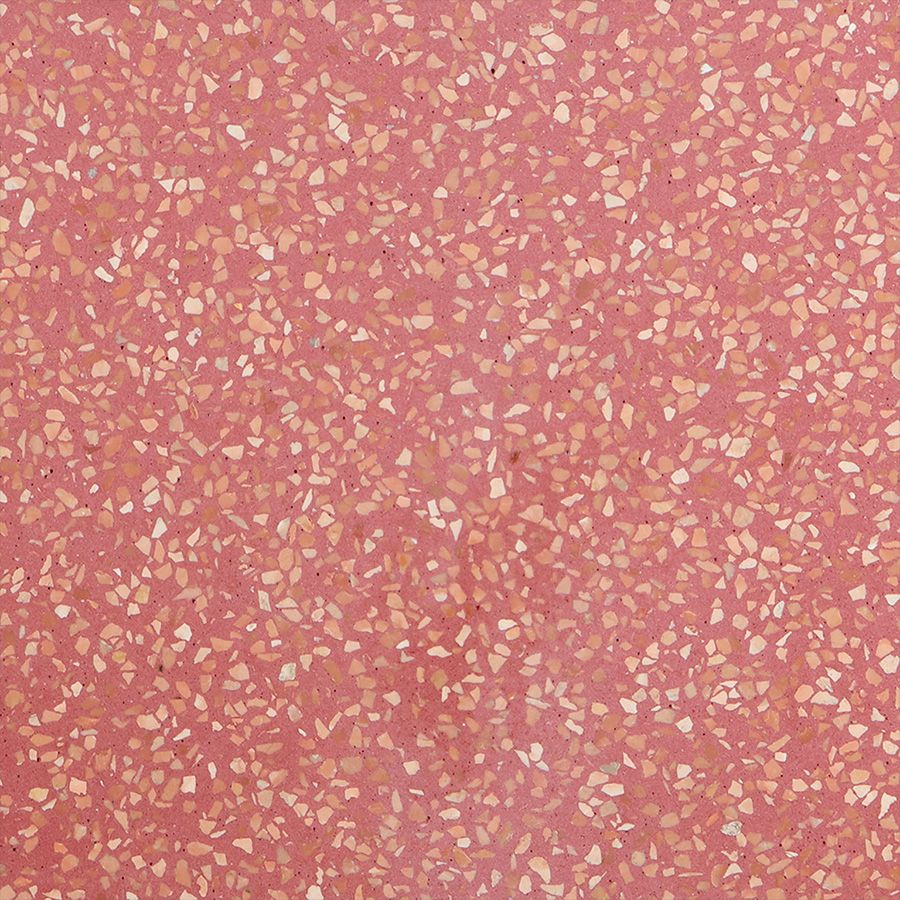

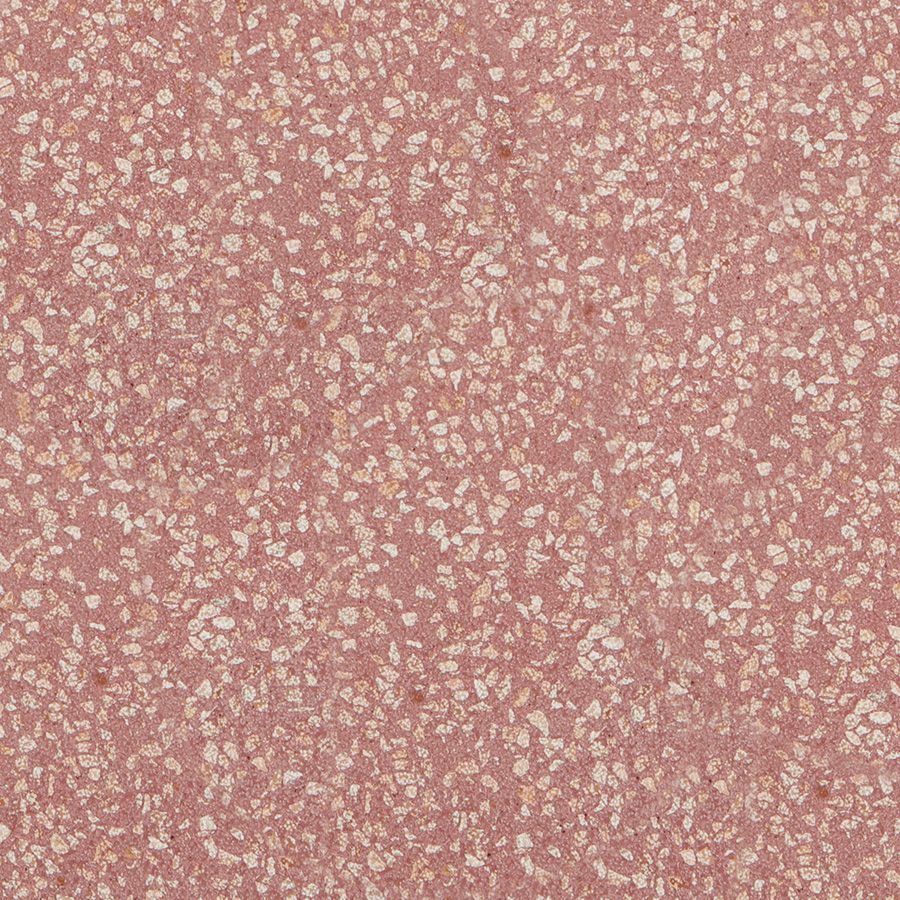

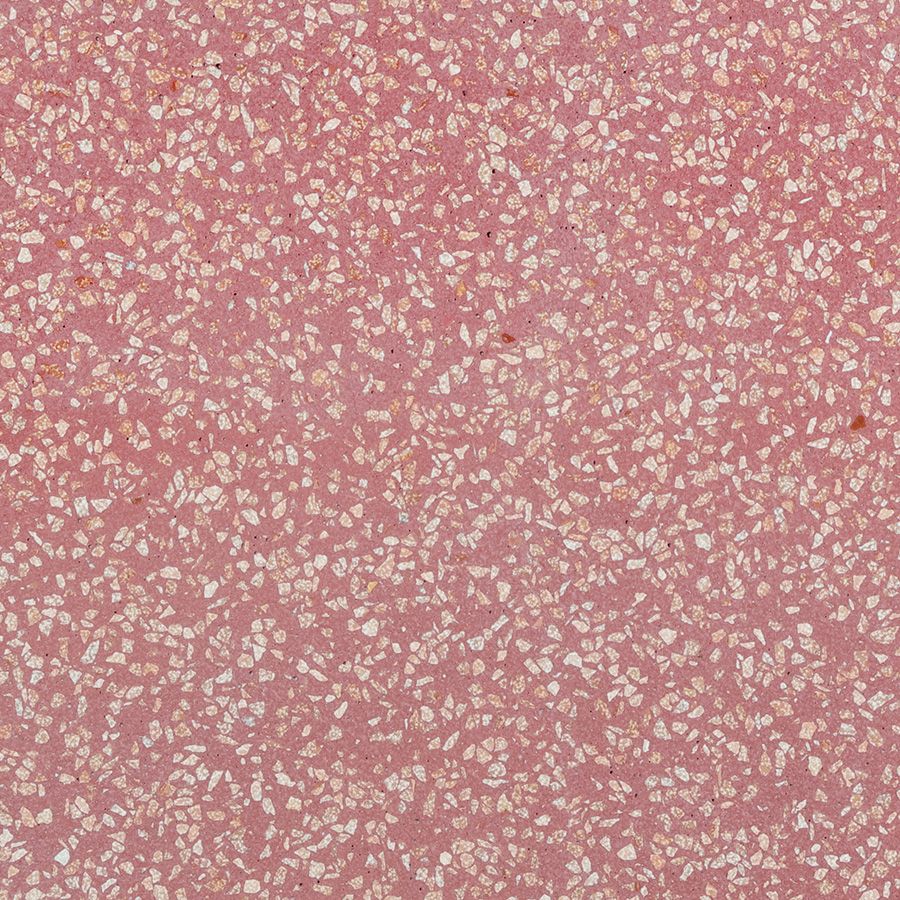

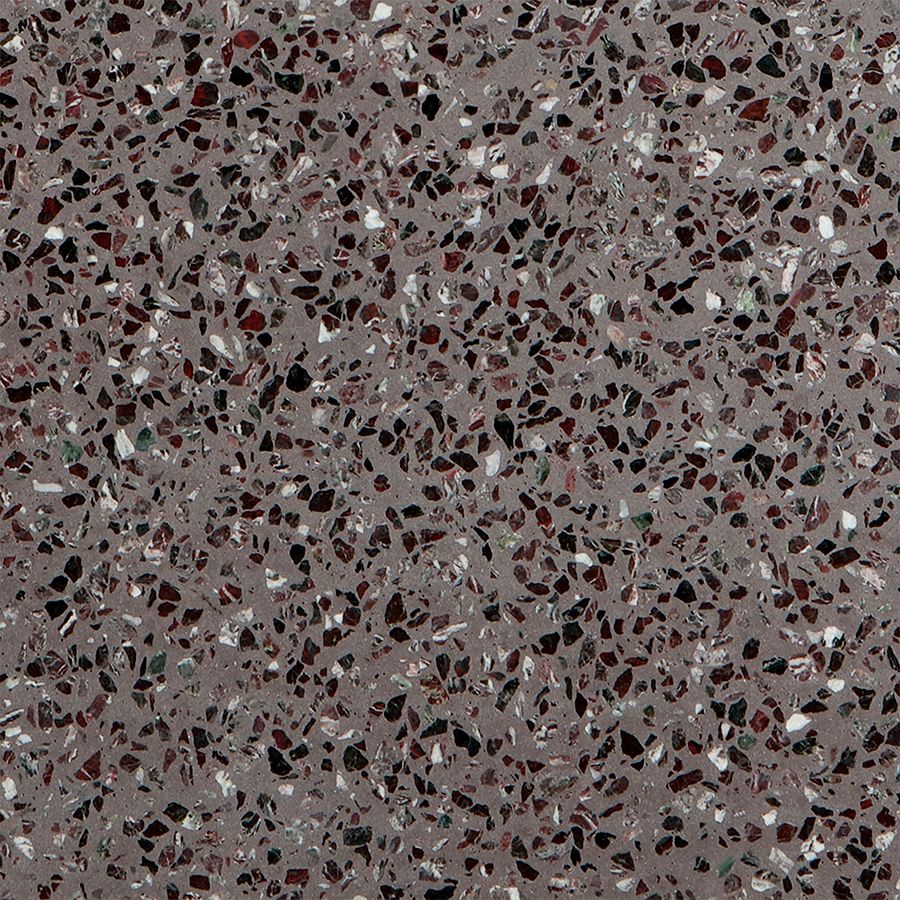

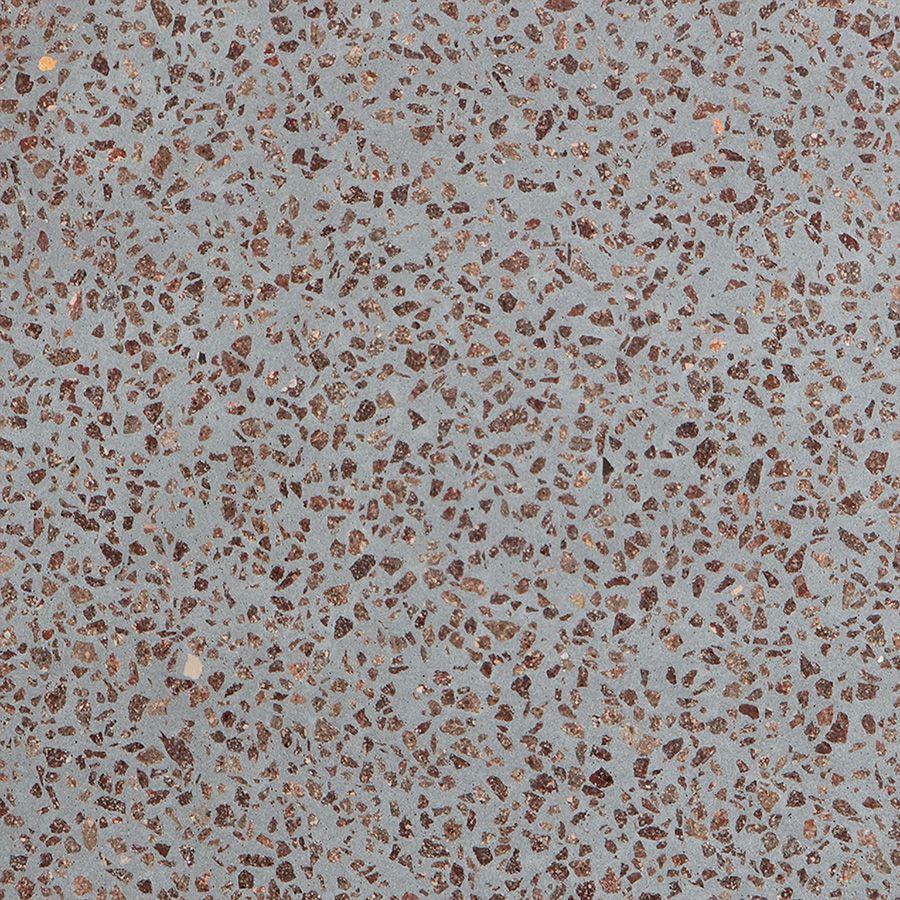

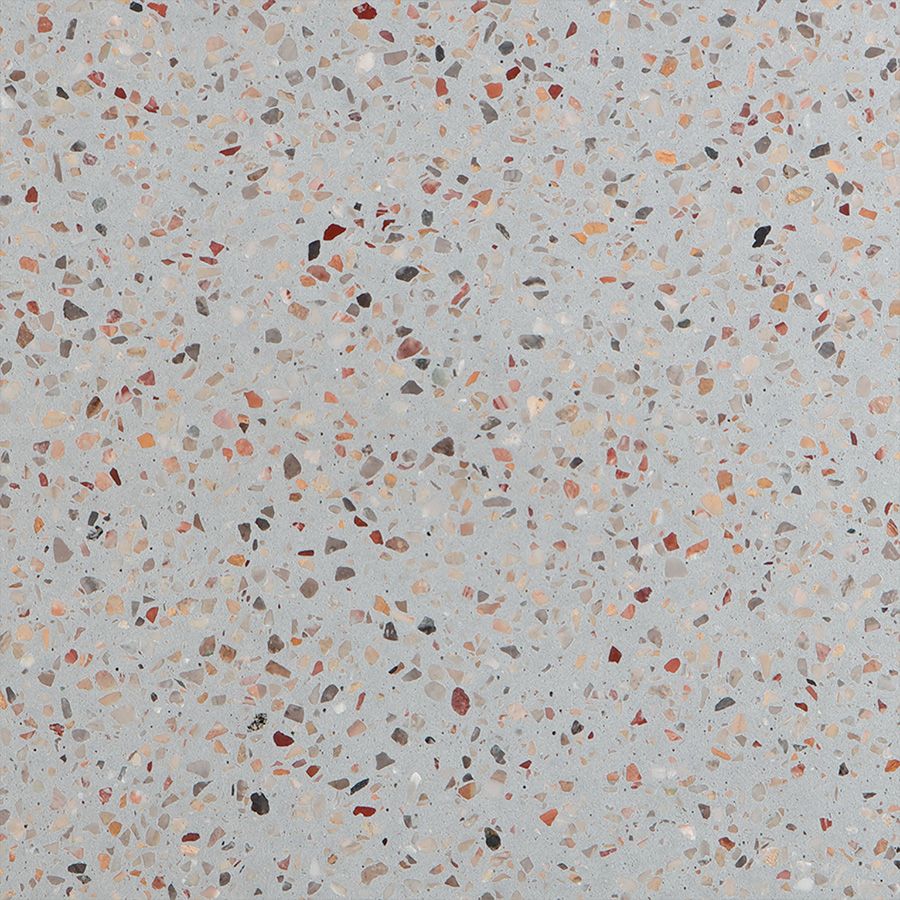

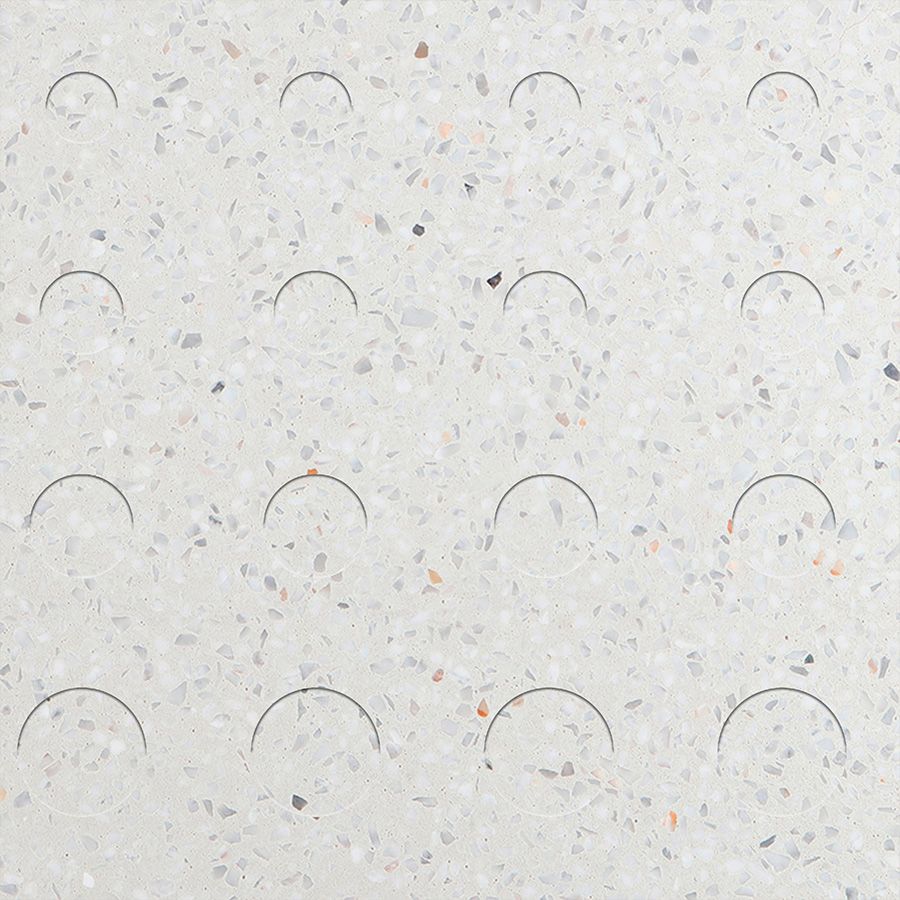

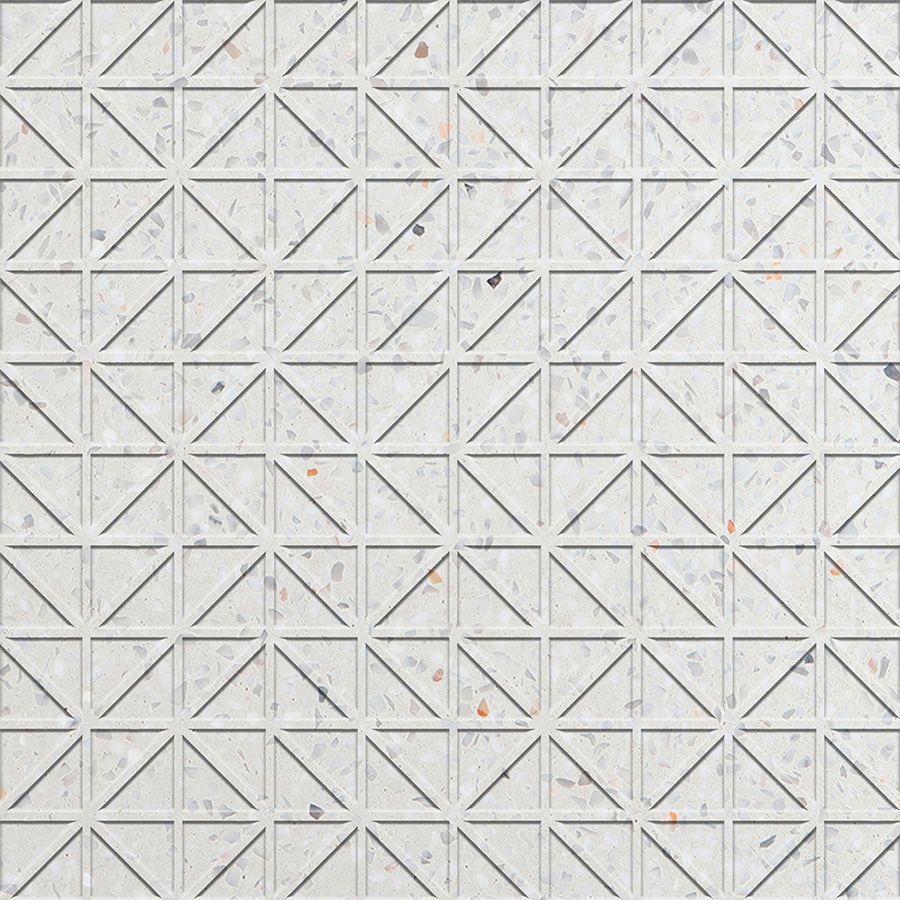

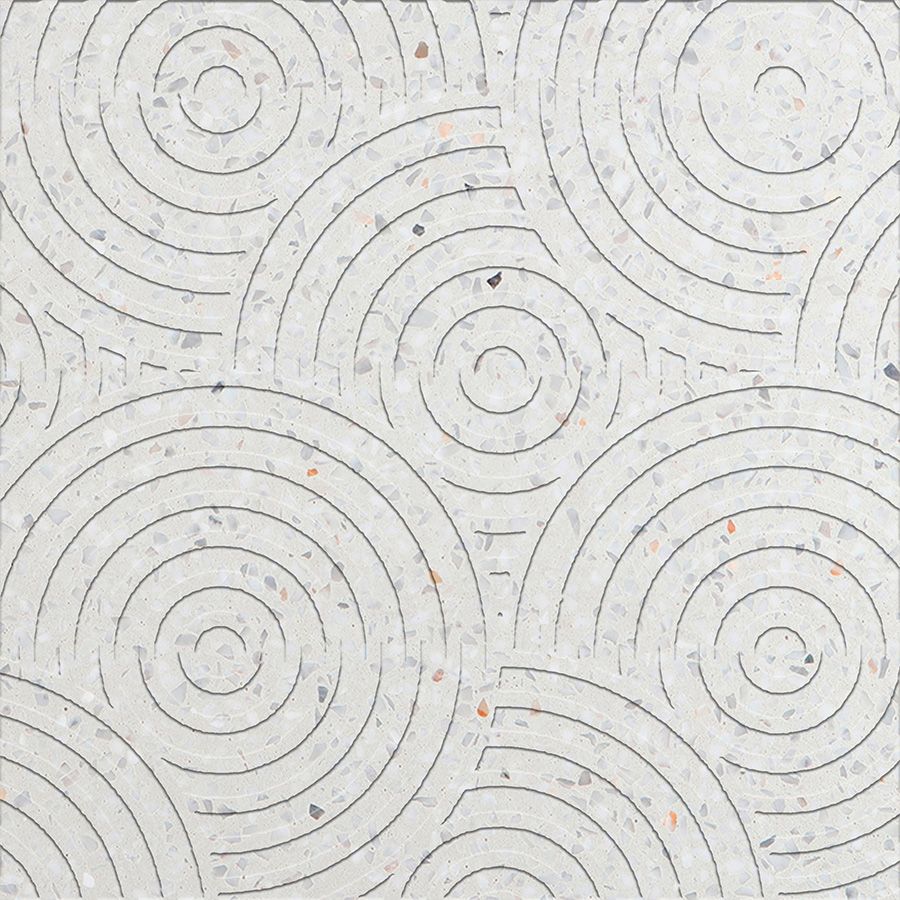

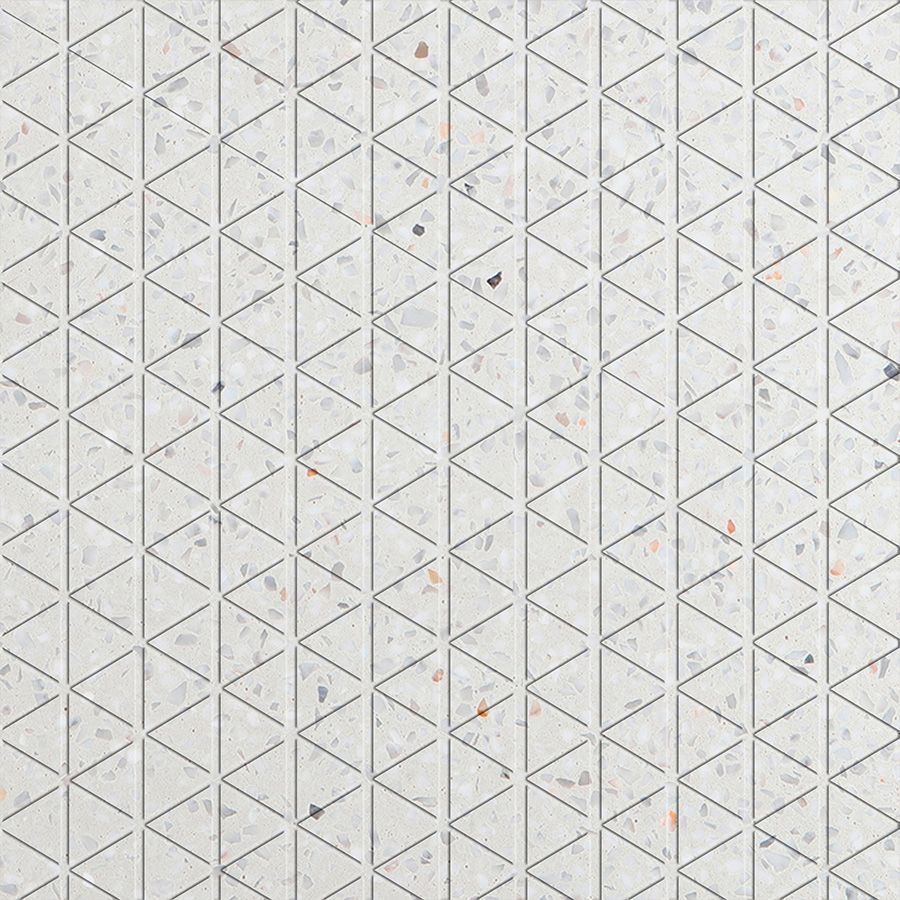

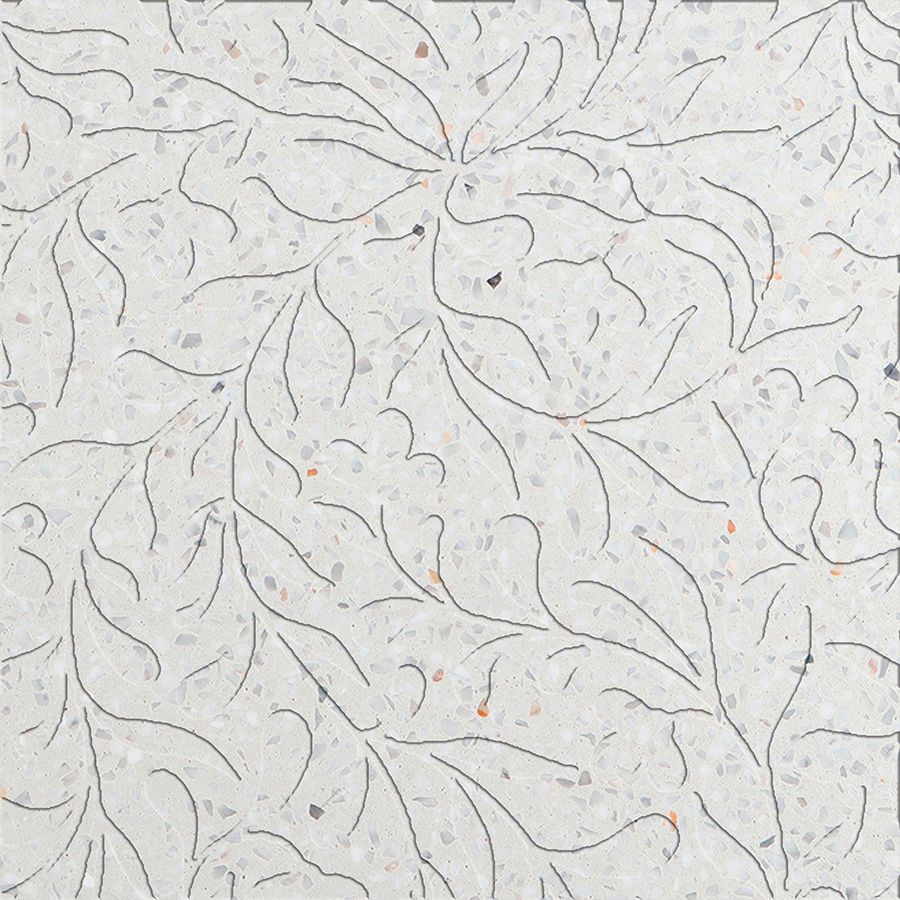

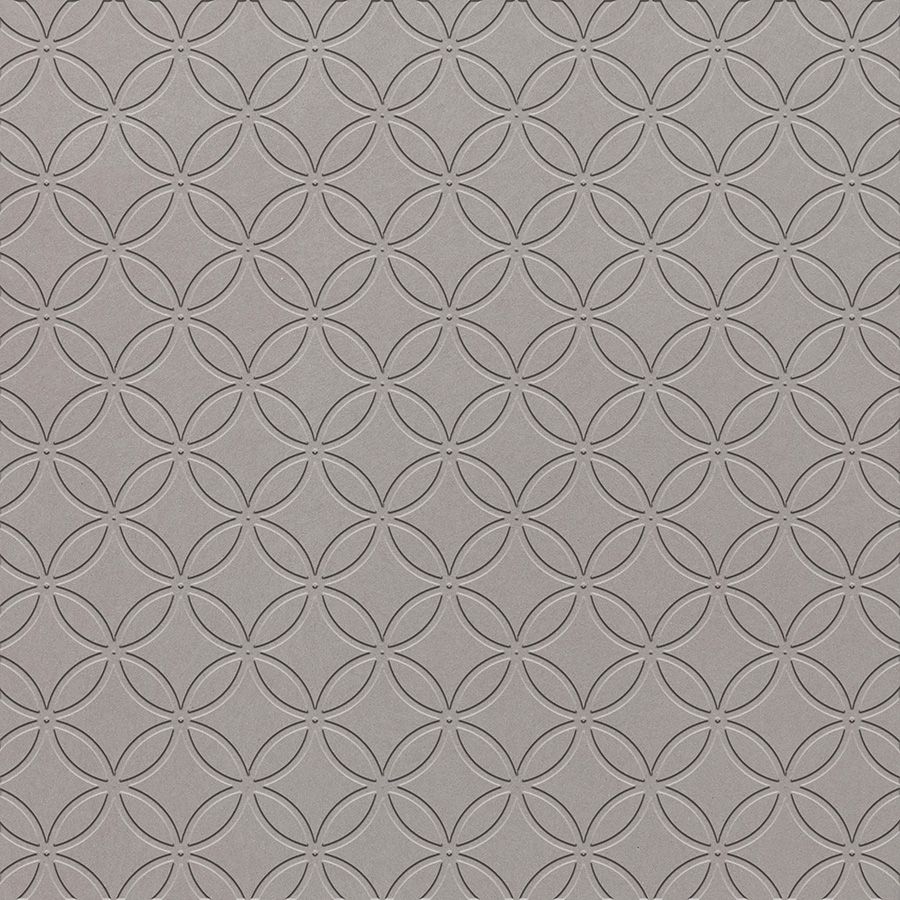

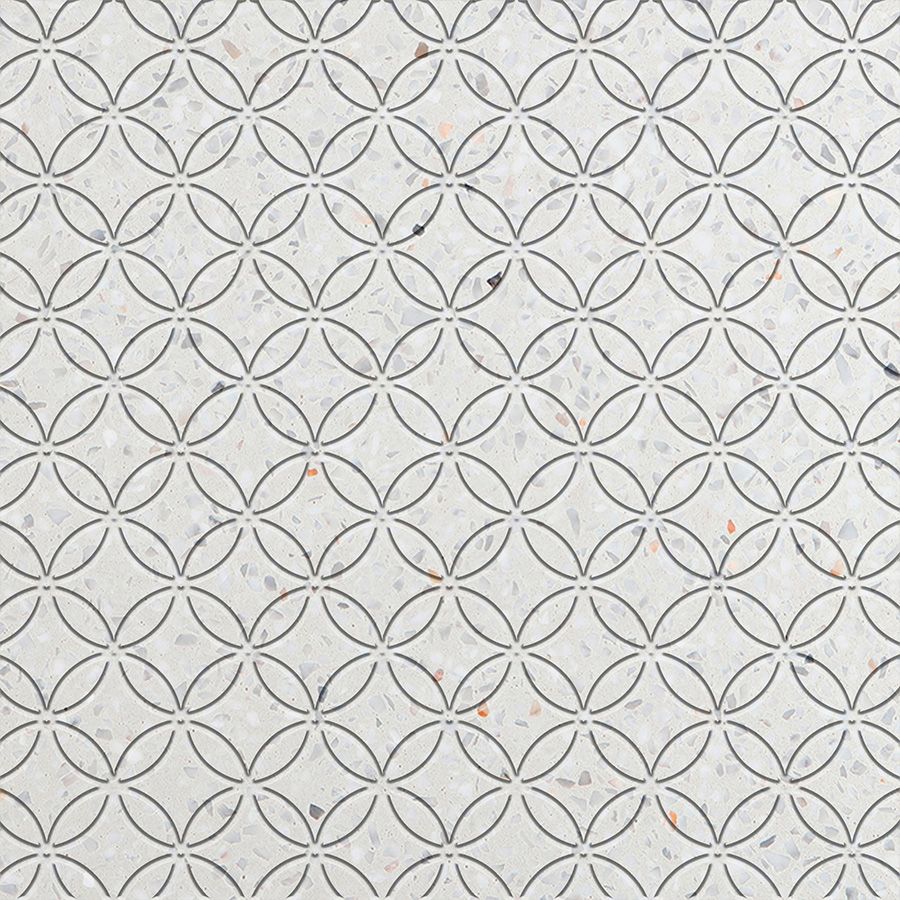

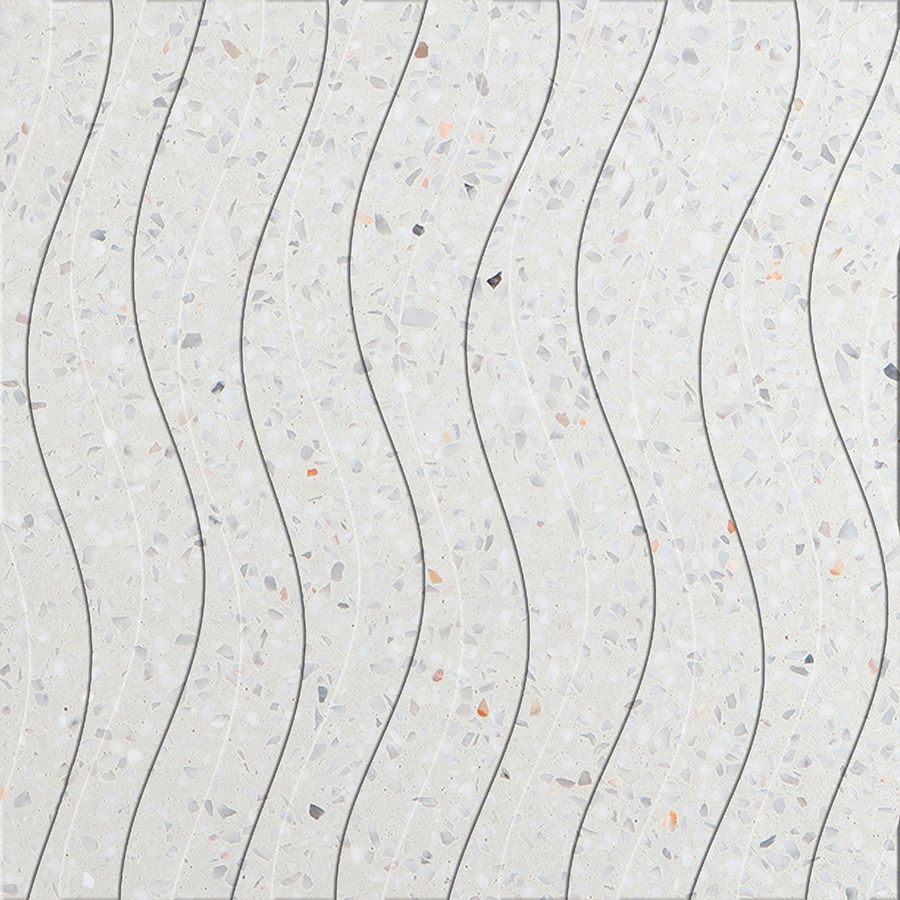

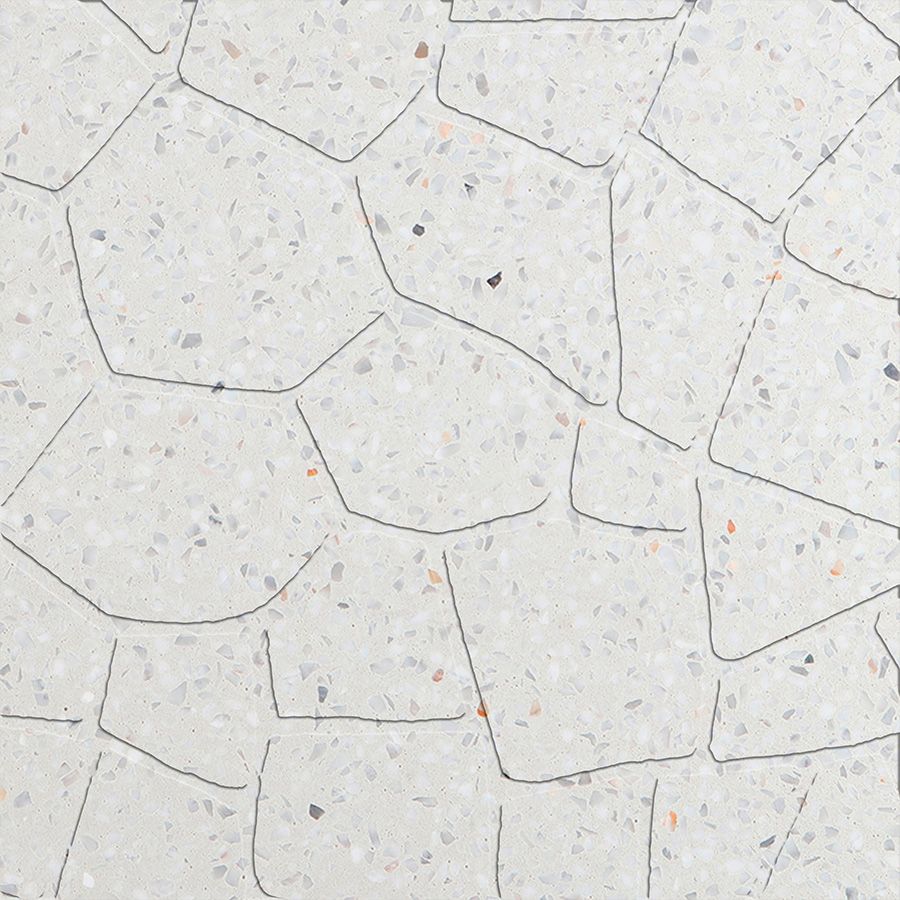

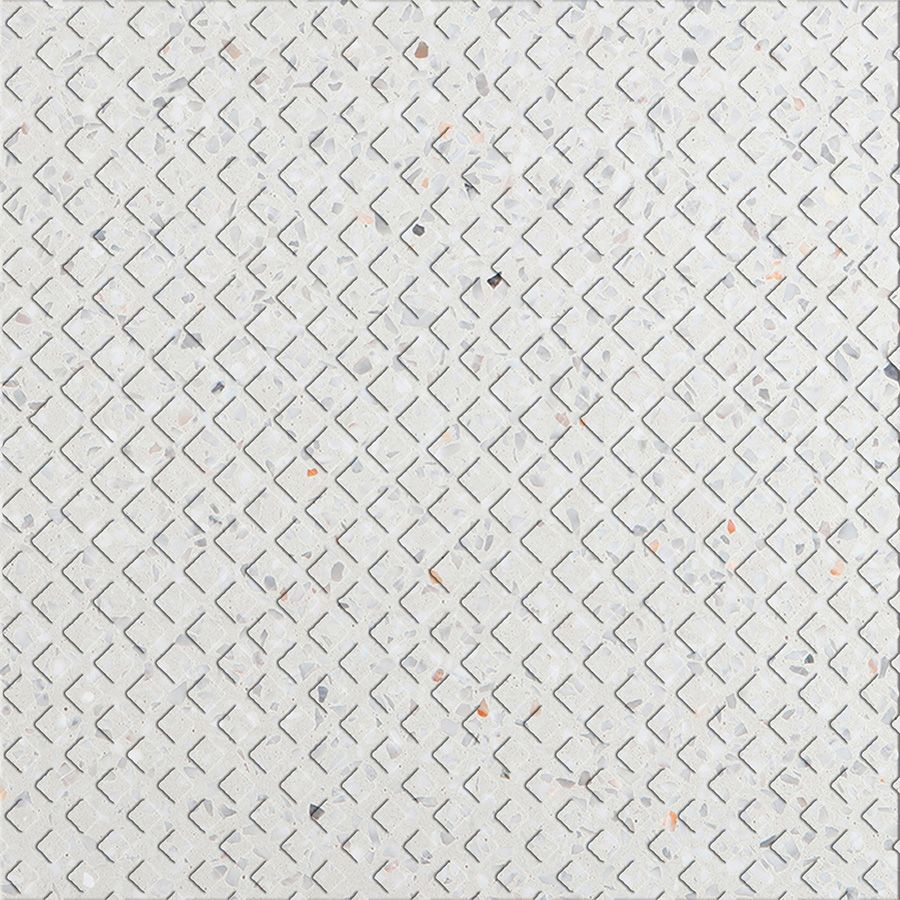

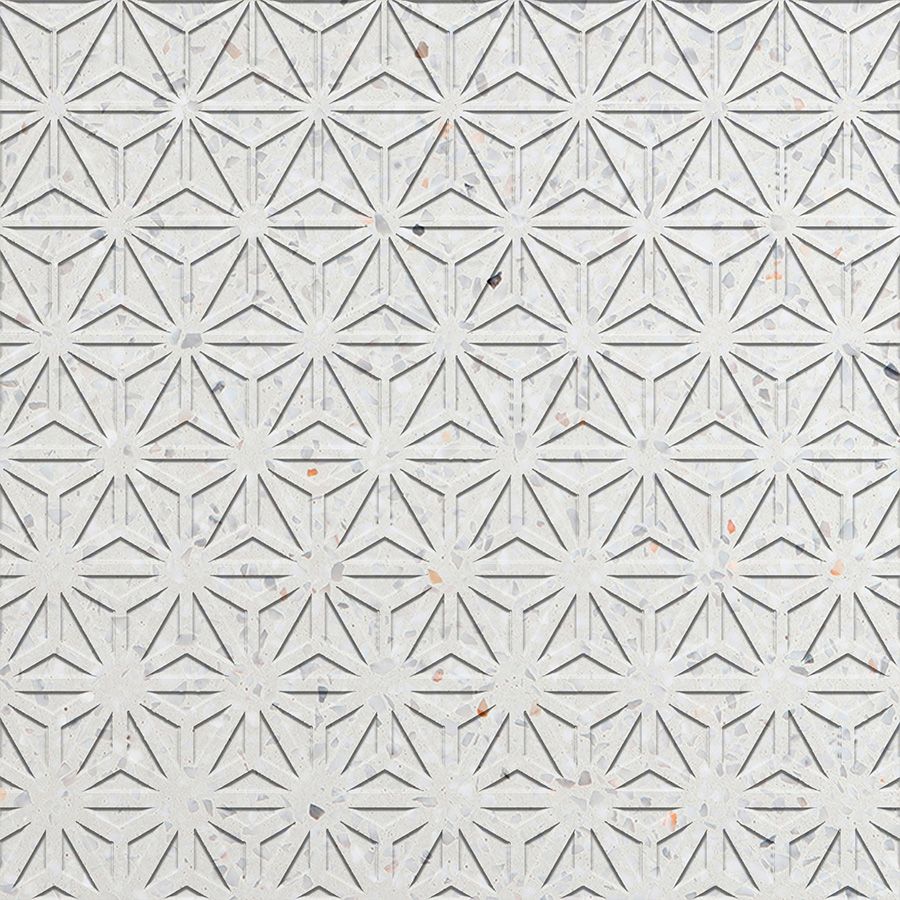

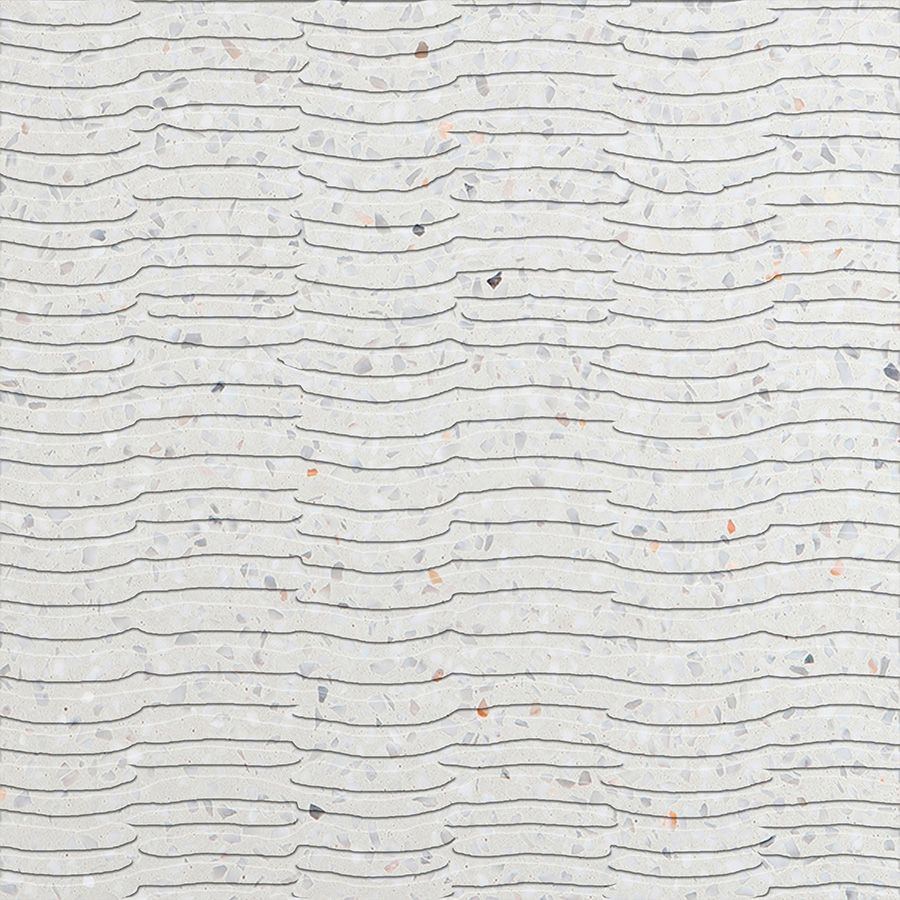

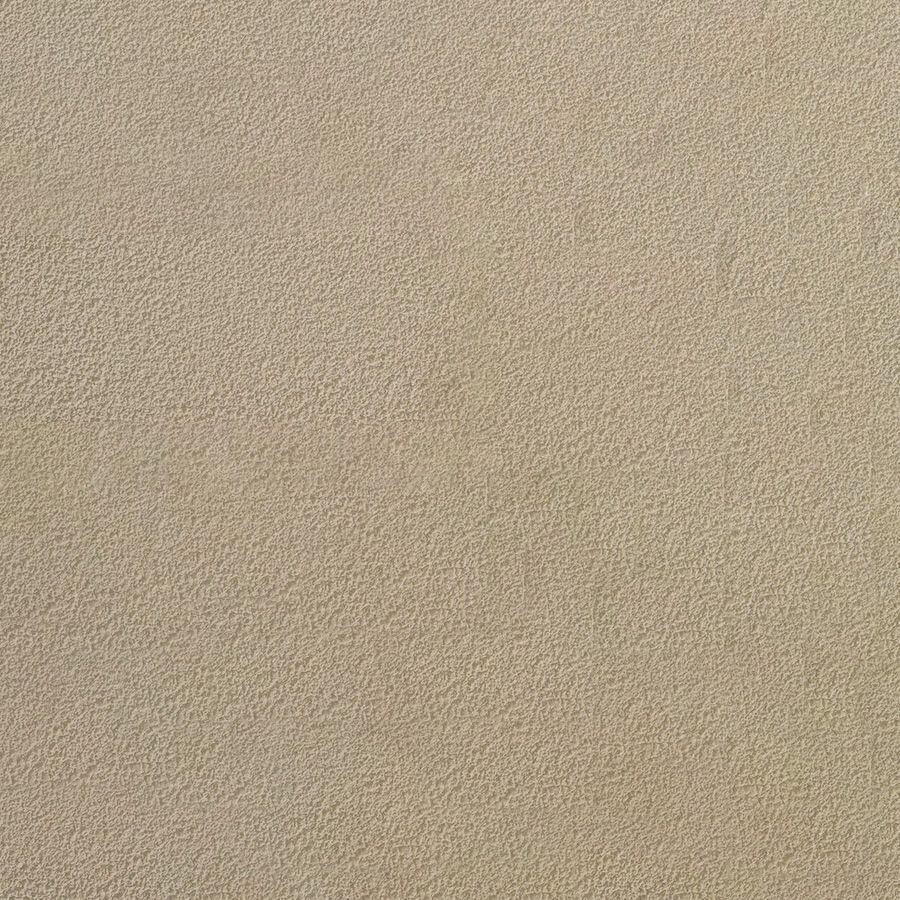

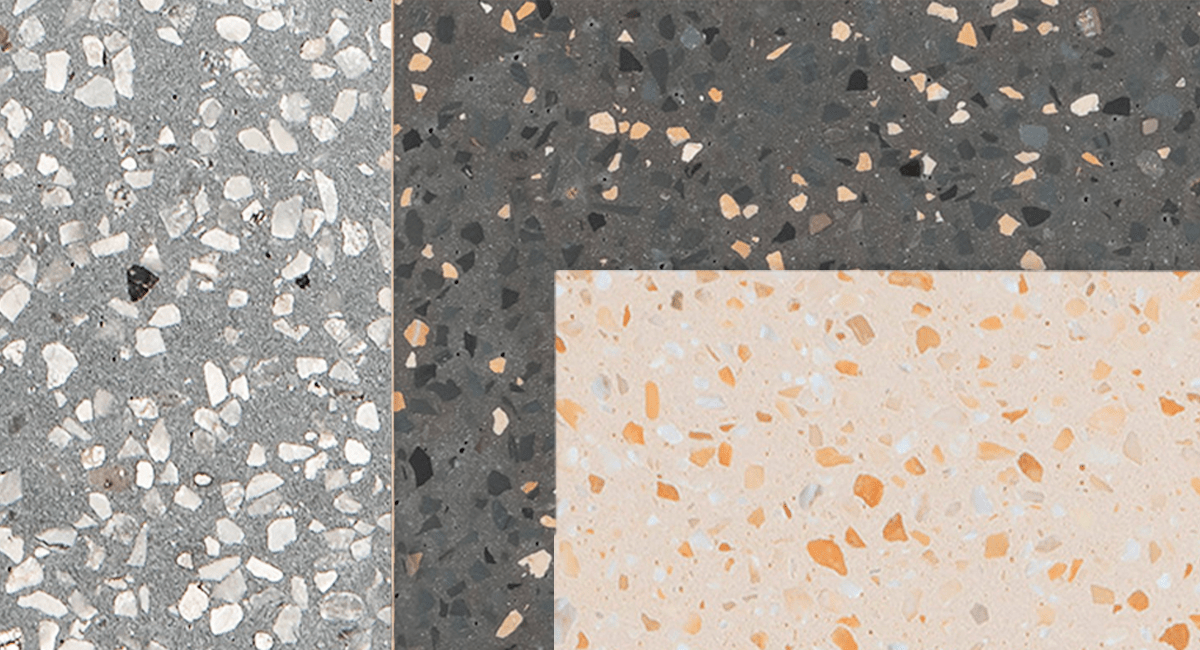

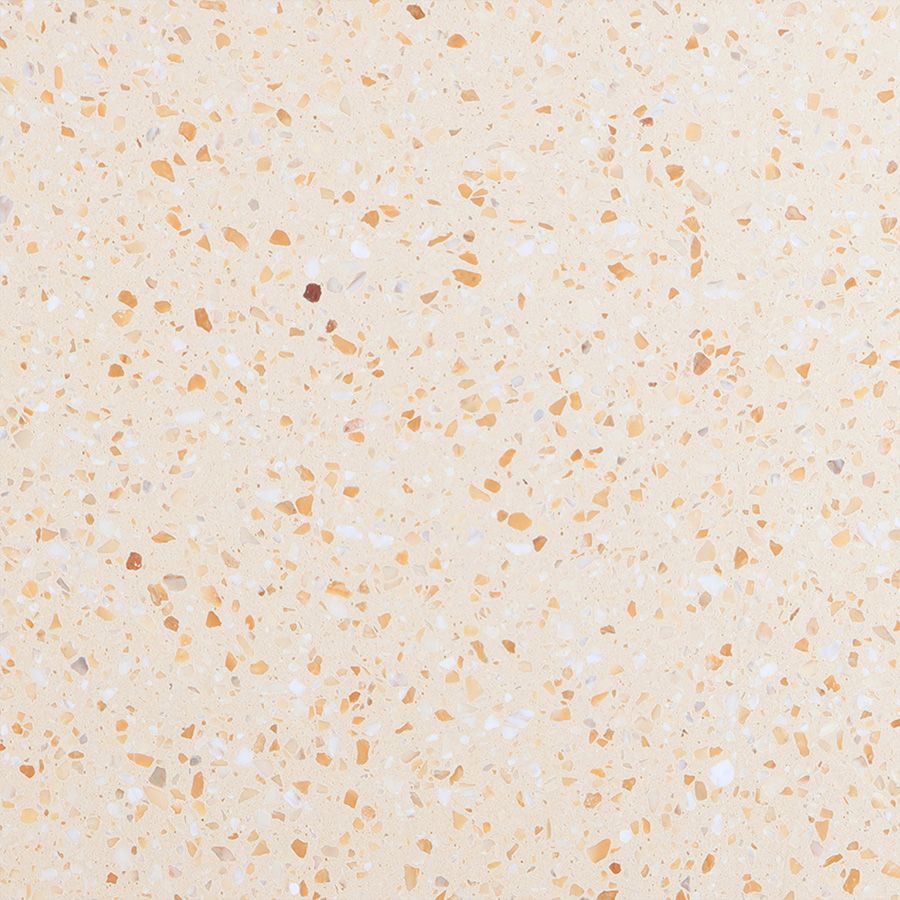

GRAIN

UHPC GRAIN is created by adding grits to the high-quality oxides we use for PLAIN, prior to the manufacturing process. The grits are made using various materials and colors, resulting in unique and inimitable variations. All colors are meticulously designed by our designers and developed after numerous color tests.

Like the PLAIN line, the GRAIN line also offers a wide range of color options with 24 different shades, providing numerous solutions for both external and internal facades. Additionally, custom products can be created upon request to meet specific needs. Our production process involves blending the color and aggregates with the raw materials, giving the UHPC an authentic and natural finish.

UHPC is an extremely versatile material and, even in the case of GRAIN colours, it can be extruded onto different matrices to take on any pattern.

Honed

Bush-Hammered

Bush-Hammered Brushed

Colors

Finishes

Colors

Sandblasting

Furthermore, thanks to our numerous collaborations, we can offer customized finishes through to sandblasting processes.

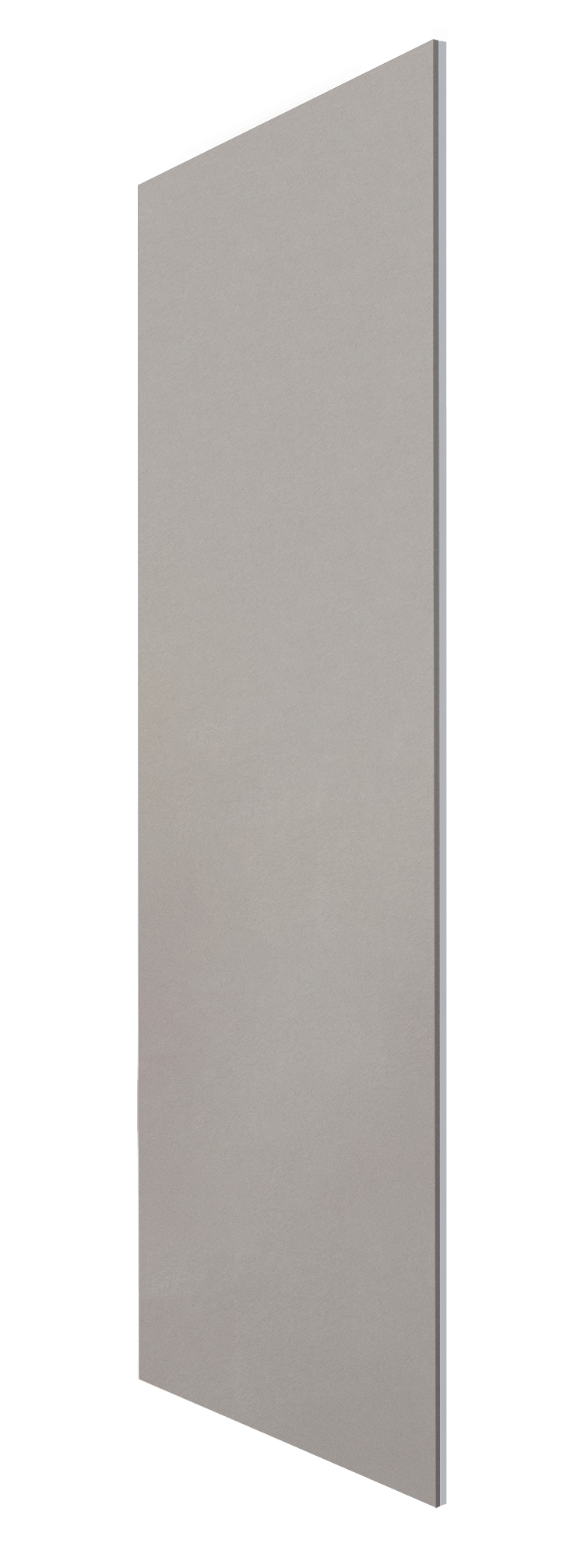

UHPC Plus Air

Panel Thickness

UHPC Thickness

Weight

Panel Thickness

UHPC Thickness

Weight