Our production

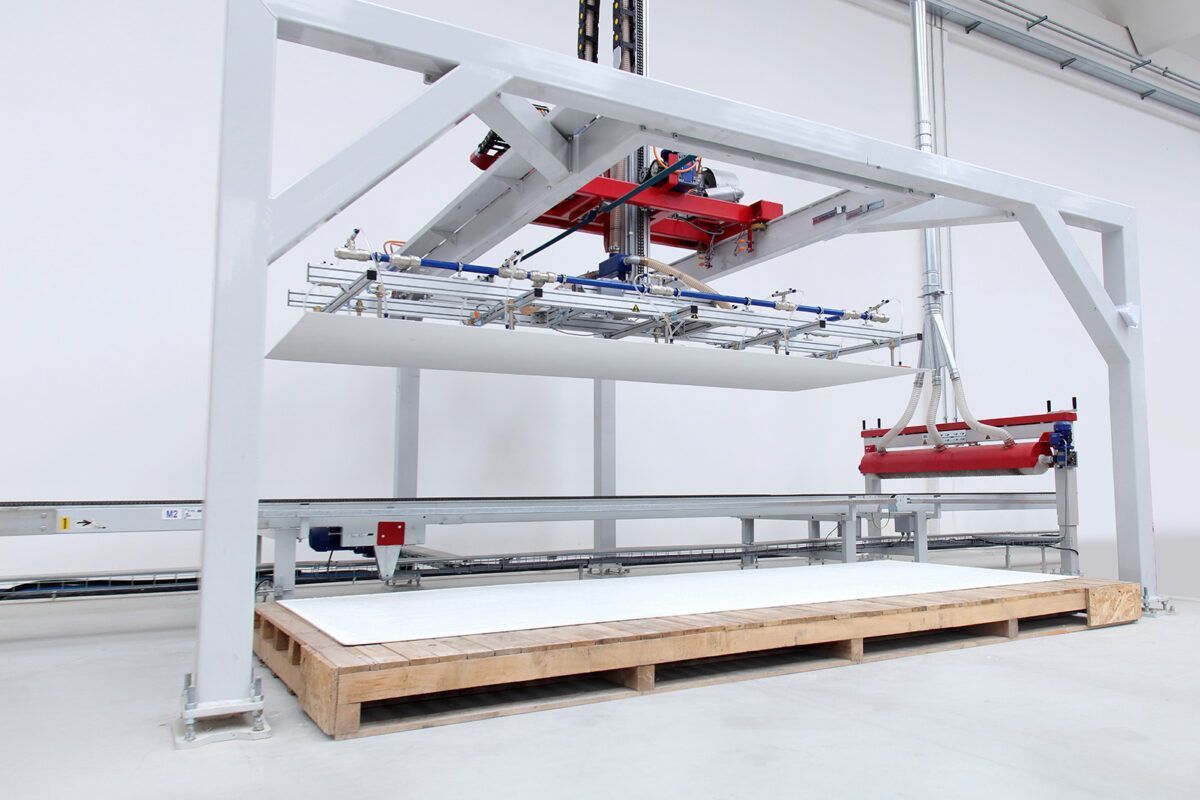

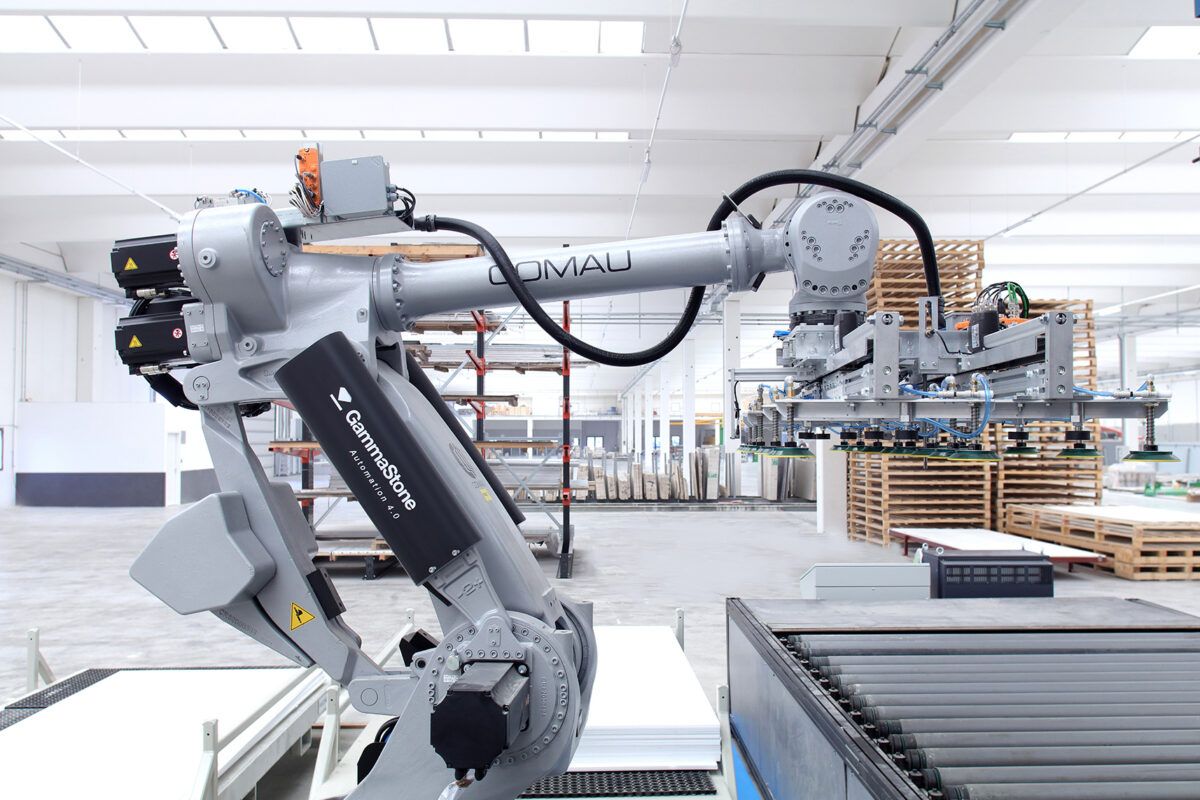

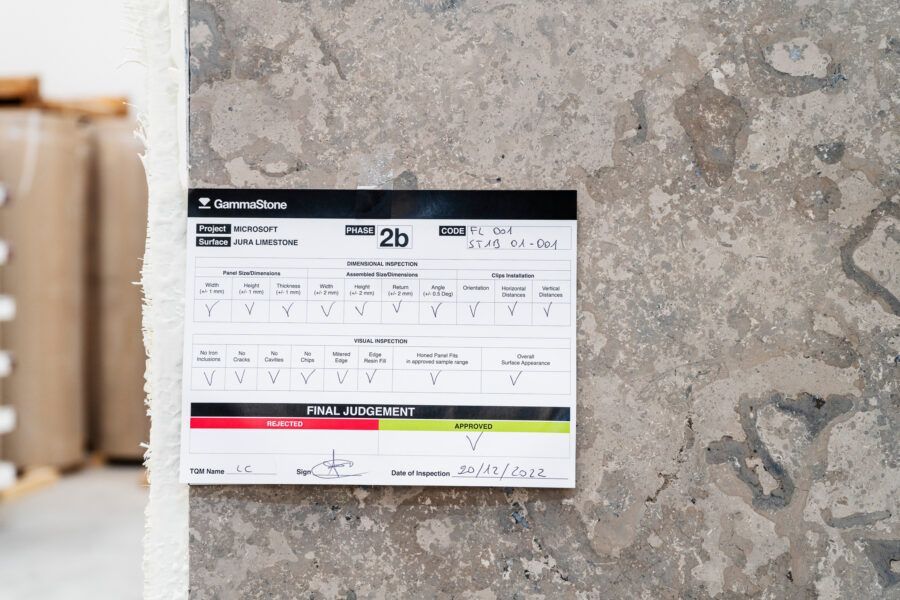

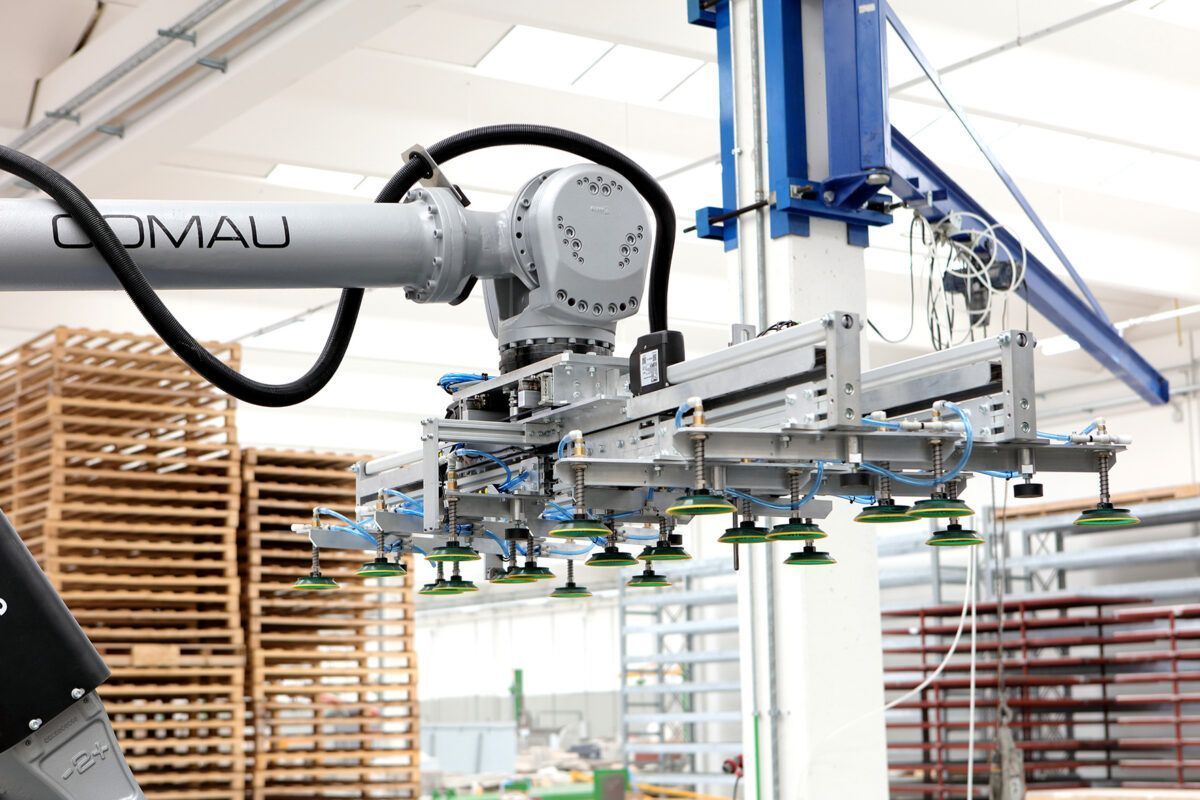

GammaStone's automated production is based on highly sophisticated machinery, which performs many of the tasks that would normally be performed manually. This includes preparing materials, cutting slabs, shaping, finishing edges and machining surfaces. In addition, GammaStone uses a fully automated quality control system to ensure that all products meet the required standards.

One of the main advantages of these processes is the reduction of production times. Therefore, the company can provide high-quality products in a short time, meeting the needs of its customers in a timely manner. In addition, automations let you reduce the labour costs, which translates into more competitive prices.

135000

Sqft Production Plant

8

Press Line

24

Assembling Work Station

4

Anthropomorphic Robot

1

Polish Line

4

Cutting Lines

3

Splitting lines

1

Heating Process

2

CNC Machines

1

UHPC Extrusion Lines