Large format up

to 4200x1500 mm

Easy installation

Lightweight

(14 kg/sqm)

Bending

Resistant

Resistant to

thermal shocks

Monolithic

Shapes

Customisable

Solutions

Large format up

to 4200x1500 mm

Easy installation

Lightweight

(14 kg/sqm)

Bending

Resistant

Resistant to

thermal shocks

Monolithic

Shapes

Customisable

Solutions

Thanks to their unique manufacturing technology GammaStone panels are designed to meet the specific requirements of the naval industry, which include lightweight construction, high levels of durability, corrosion resistance, and the ability to withstand harsh marine environments.

These panels, typically designed for interior and exterior wall or ceiling cladding, utilize patented Air Technology that makes them lightweight, durable, easy to install, moisture-resistant, corrosion-resistant, and easy to clean. Furthermore, to meet the specific requirements of each ship or equipment, they undergo rigorous testing to ensure their longevity and performance in marine environments.

The innovative GammaStone panels offer a range of unique advantages that make them the perfect solution for your design and performance needs. Our panels allow to realize stunning interiors and exteriors, ensuring reliable and long-lasting performance. Choosing GammaStone lightweight panels for the naval sector means obtaining a high-quality, durable, versatile, and sustainable product.

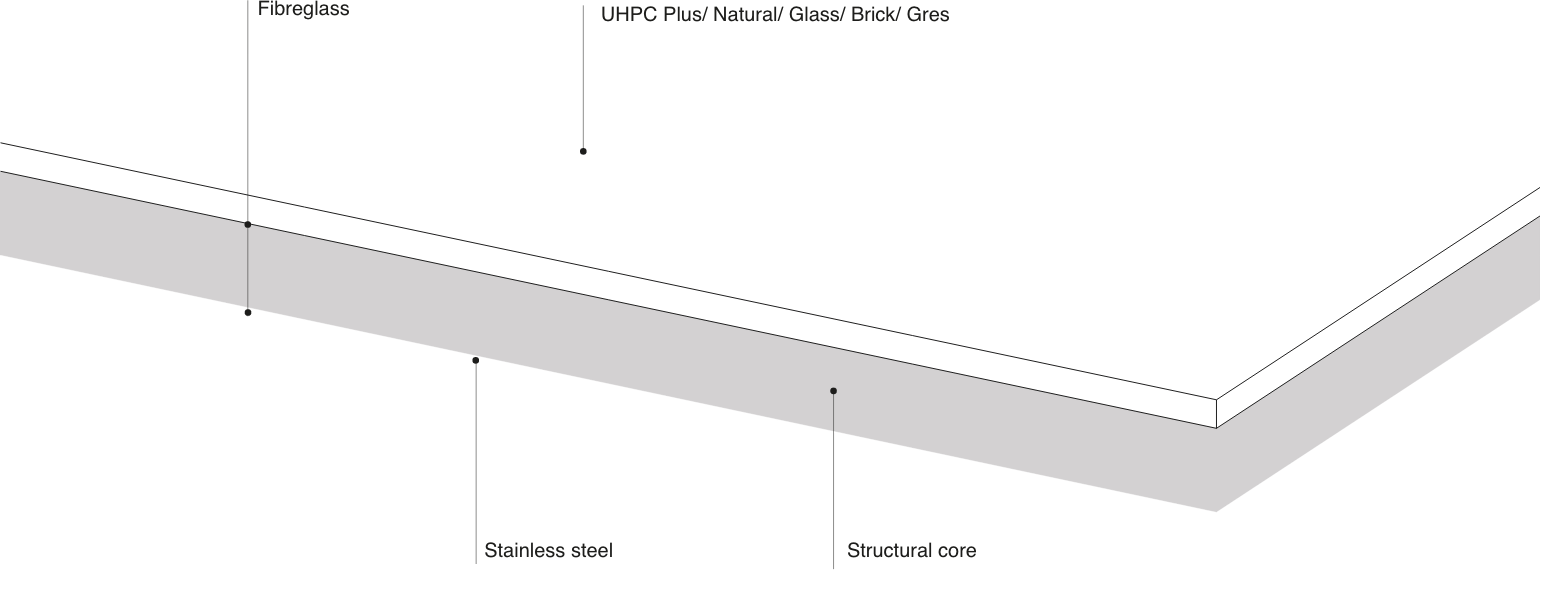

GammaStone lightweight panels are made using high-quality materials such as marble, UHPC (Ultra High-Performance Concrete), glass, and gres porcelain, combined with a lightweight core. This results in a significant reduction in the overall weight of surfaces, enabling greater energy efficiency, improved maneuverability of ships, and increased load capacity.

GammaStone panels maintain superior weather resistance. Our advanced production process ensures that the materials are perfectly integrated, creating a highly weather-resistant solution that can withstand extreme marine conditions. GammaStone panels can endure corrosion and abrasion, guaranteeing exceptional durability over time.

Despite their lightweight construction, GammaStone panels maintain superior structural strength. The combination of materials with the steel base creates a layered structure that enhances strength, providing a highly performing solution against mechanical and physical stress. The panels undergo specific tests to withstand tensile, flexural, and impact strength.

Thanks to the range of available materials, GammaStone panels offer endless design possibilities to create unique and sophisticated environments on board ships. Whether you seek the classic elegance of marble, the refined modernity of glass, or the timeless robustness of porcelain stoneware, our panels can be customized to meet your most demanding aesthetic desires.

GammaStone panels are designed to simplify the installation process, reducing time and costs. Thanks to their reduced weight, they can be easily handled and mounted, ensuring quick and efficient installation. Additionally, their smooth and non-porous surface makes cleaning and maintenance a simple task, reducing ship downtime and associated costs.

GammaStone is committed to providing sustainable solutions. Our panels are made with eco-friendly materials, reducing environmental impact without compromising on quality. Moreover, the lightweight nature of GammaStone panels contributes to increased energy efficiency in ships, reducing fuel consumption and CO2 emissions.

The GammaStone Air Technology system makes our panels extremely lightweight and available in large formats. Every feature is fully customizable to effectively meet diverse needs. The range includes applications with natural stone, UHPC, porcelain stoneware, glass, and brick.

Natural stone panel

of the latest generation and millennial charm

Concrete ultra-high performance panel

extremely lightweight and extremely resistant

Panel in facing bricks, klinker and functional and tidy gres

Ultra-light and eye-catching

back painted glass panel

Porcelain gres panel

high-quality and outstanding performance

Max Panel Sizes

3200×1500 mm

Max Panel Sizes

4150×1650 mm

Max Panel Sizes

3000×1000 mm

Max Panel Sizes

4200×1500 mm

Max Panel Sizes

3200×1500 mm

GammaStone produces large-sized monolithic columns that are pre-assembled and ready to be installed.

Sizes

2500×1200mm

Stone Thickness

5mm

Corner

90°

The main characteristic of the GammaStone Air system is its high level of workability and versatility. The panels are cut at various angles, welded, and reinforced with metal structures, forming a unique monolithic architectural element that satisfies a wide range of aesthetic and functional requirements for buildings. These unique elements allow us to produce columns, stringcourses, and any complex architectural shape to meet any designer's request.

To ensure their compliance with safety, quality, and performance standards, certification of panels in the naval sector is crucial. In fact, GammaStone panels results complied with the requirements of the Marine Equipment Directive (MED) 2014/90/EU, including the testing requirements and standards of Regulation (EU) 2017/306.

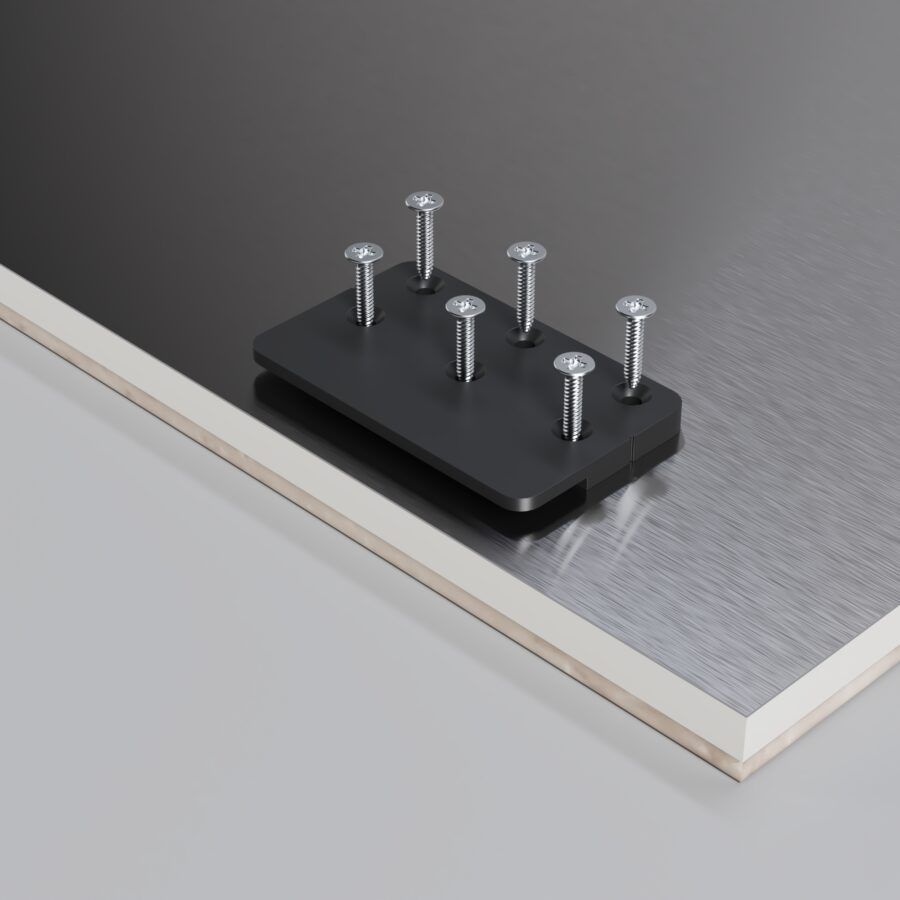

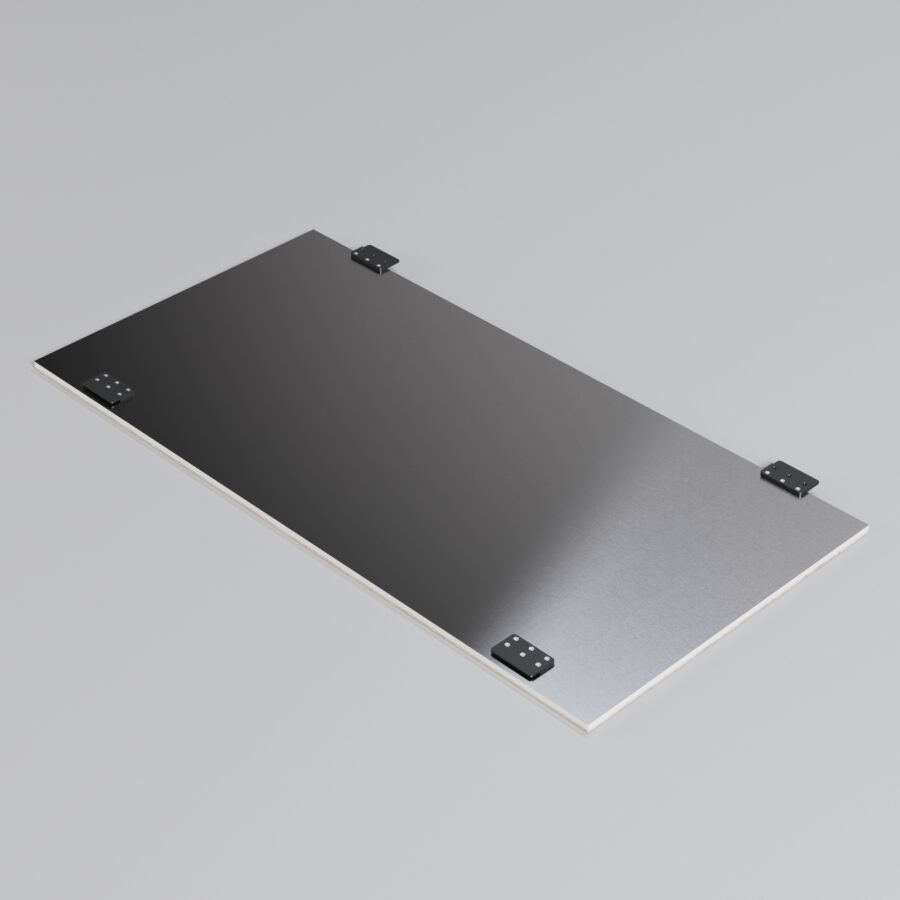

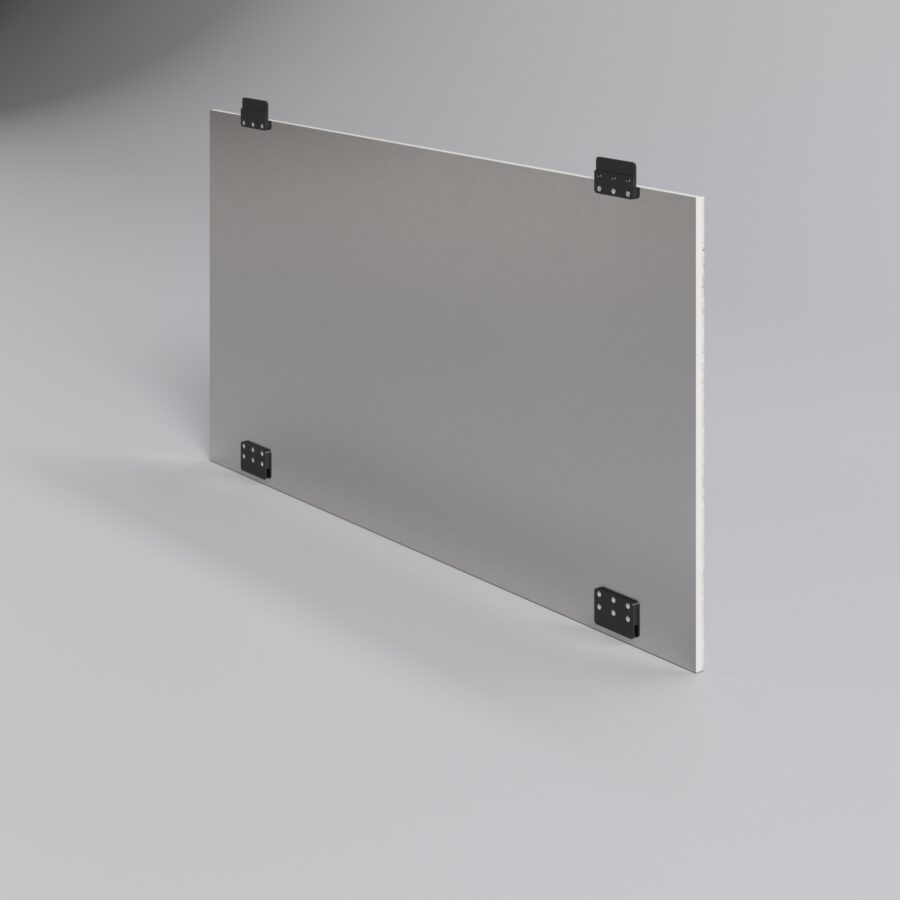

The installation of GammaStone panels involves a simple fixing system that allows savings in terms of installation time and costs. This system includes components such as screws and brackets that ensure a secure and stable connection between the elements, withstanding vibrations and climatic stresses. Additionally, to prevent water from penetrating the cavities, silicone is used for joint sealing, which can be matched or contrasted with the color of the wall, ensuring a more durable assembly. This component not only enhances the product's performance but also provides a smooth and uniform surface, adding a high level of project customization.

Basic bracket

Upper bracket

Panel with perimeter brackets

Panel ready for anchoring