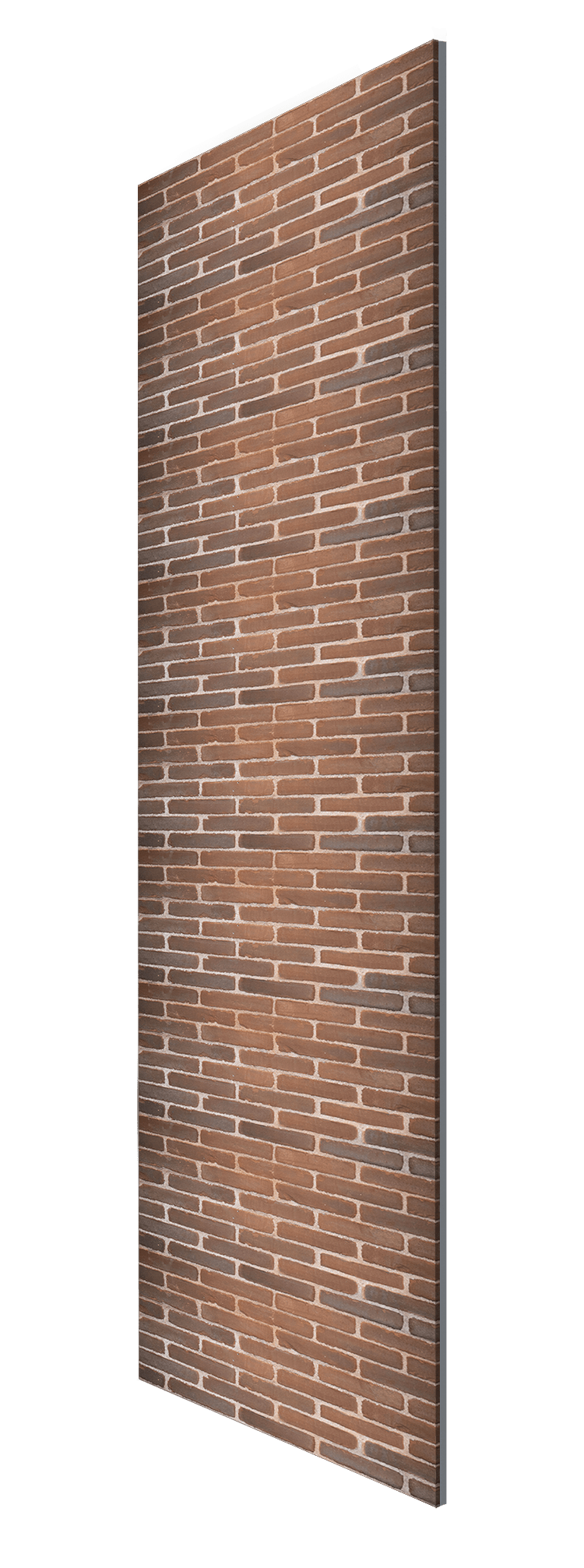

This solution allows the dry installation of brick panels, ensuring the advantage of rapid application and wonderful aesthetics. The Brick Air panel is supplied and pointed with mortar ready for installation. Choosing the Brick Air panel means opting for a timeless beauty solution that also lends itself well to buildings equipped with a modern structure. The joints between the panels are designed to ensure a unique effect on the entire façade. Thus, the drainages of these panels, whose production is supported by the most innovative technology, can boast incredible linearity, both vertically and horizontally. In this way, we can contribute to the construction of magnificent skyscrapers, which can boast a single escape: linear from the ground to the top floor.

It is a meticulous processing, which requires extreme precision in the different manufacturing phases carried out within our production plant. Here we use state-of-the-art engineered systems, which allow us to align the leaks as it would not be possible to do in operation with traditional methods. Each brick is positioned with an extraordinarily effective specific offset, which guarantees as a result a truly exceptional product. This feature provides great appeal on the building's final result: it ensures speed of installation and offers a highly rational, particularly accurate visual impact.

The patented GammaStone Air panels are produced by cutting-edge automated 4.0 systems that allow them to be created in large format.

Thanks to our experts, we are able to create extremely light coatings with very high resistance to impacts, bending and compression.

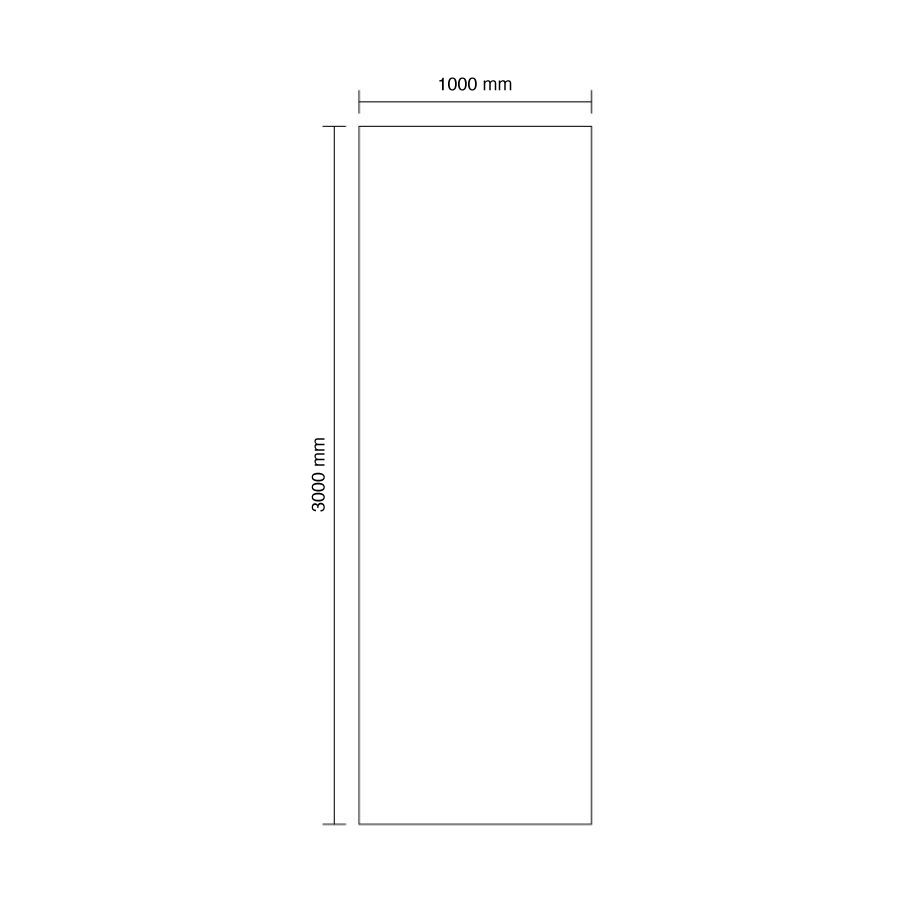

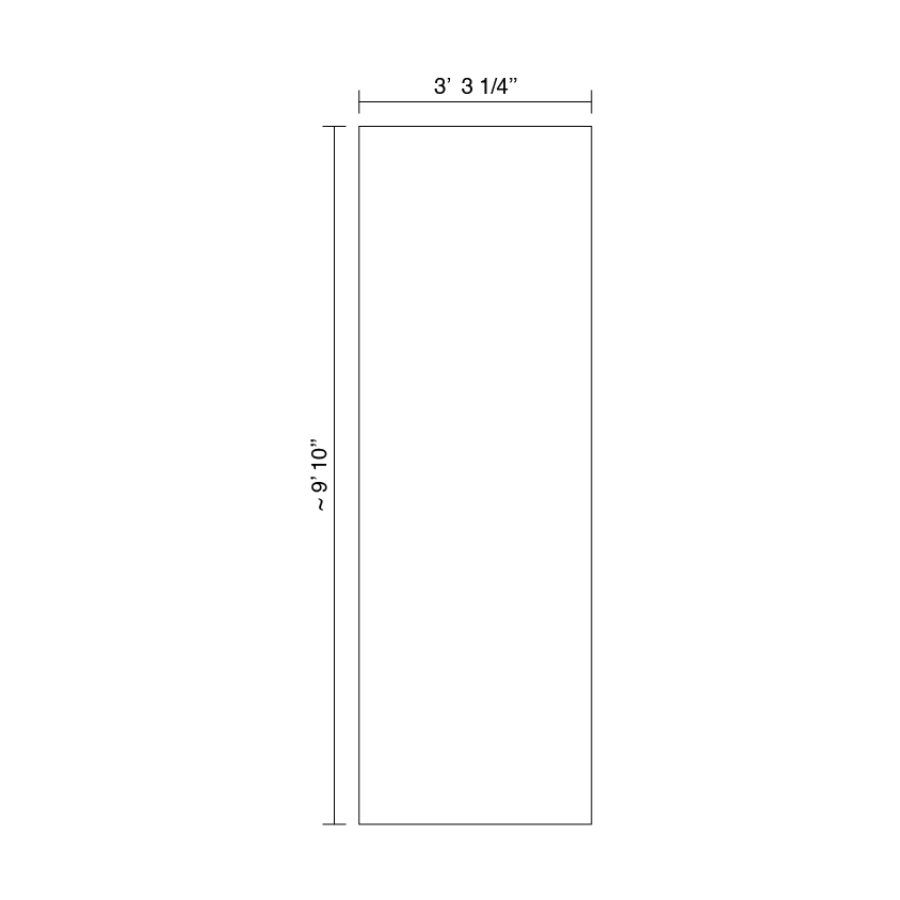

Our panels are made with innovative materials used in the aerospace industry and can reach 3000×1000mm in the Brick version.

At GammaStone we have the ability to make each project unique, even by choosing bricks as a solution.

Being able to count on decades of experience in the use of these materials, we are certain of guaranteeing a very high quality service.

Our goal has always been to best enhance the originality of each project.

Each project entrusted to us is unique and is developed based on specific requests from the architects, both from an aesthetic and structural point of view.

Air Technology adapts perfectly to any type of structure and allows you to choose from countless types of solutions.

Brick Air is available in a large customizable format with the possibility of dry anchoring systems.

The Brick Air panel can be made by opting for a zip or no zip solution, i.e. panel.In the first case the escape is, so to speak, hidden between the various bricks and then sealed with special silicones of the same colour: the resulting effect is not that of a subdivision into panels but of a single façade. In the second case, however, the structure of the single panel is enhanced.

Zipped

Zipped

No zip

The bricks can be made using different materials: Facing bricks, Klinker and Gres.The first corresponds to a solution of great value, in great demand and already widely used on projects of a different nature. However, for GammaStone it is crucial to offer other opportunities, so that the result responds perfectly to the architect's desire.

Facing bricks - Nice

Facing bricks - Nice

Facing bricks - PGWA

Facing bricks - VRWA

Facing bricks - GBWA

Facing bricks - Irvine

Facing bricks - MNWA

Facing bricks - Princeton

Facing bricks - Sherwood

Gres - Ebony

Gres - Layering

Gres - Niveum

Klinker - Platin

Klinker - Viktoria

Klinker - Big Ben

Klinker - Dharma Style

Klinker - Escape

Klinker - Fold

Klinker - New York

Klinke - Iron

Total thickness

Brick thickness

Weight

Total thickness

Brick thickness

Weight

Total thickess

Brick thickness

Weight

Total thickess

Brick thickness

Weight