The working process at GammaStone

From the preliminary design phase that focuses on assistance to the designer to strategic consulting with customised solutions, through planning and production and then to transport and installation. We discover all the stages of the work process in GammaStone, where each step is personalised to carry out a complete, exhaustive and high-quality service. We study logistical and implementation synergies to share with you to enhance the projects, respecting the qualities with which they were conceived.

Set-up

Co - Design customise

Feasibility study with the Architectural Firm - Technical-economic proposal to architecture studio - Assistance to the Architectural Firm for design

Custom Sample

Colour definition and finish with architect - Custom sample production - Approval

Certification

Assistance to the consultant for technical aspects

and certifications

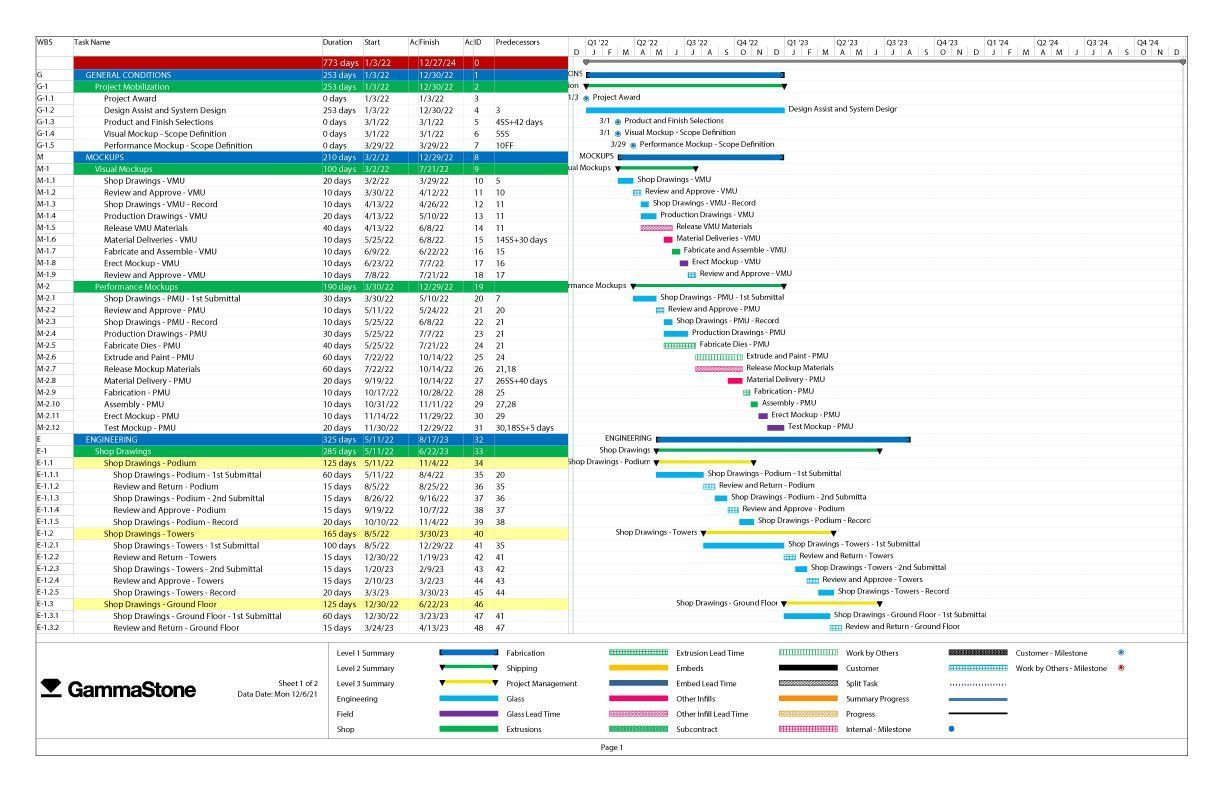

Plan

Order definition with customer / general contract - Time schedule definition

Execution

Mock up

Sample Approval - Visual Mock up - Performance Mock up

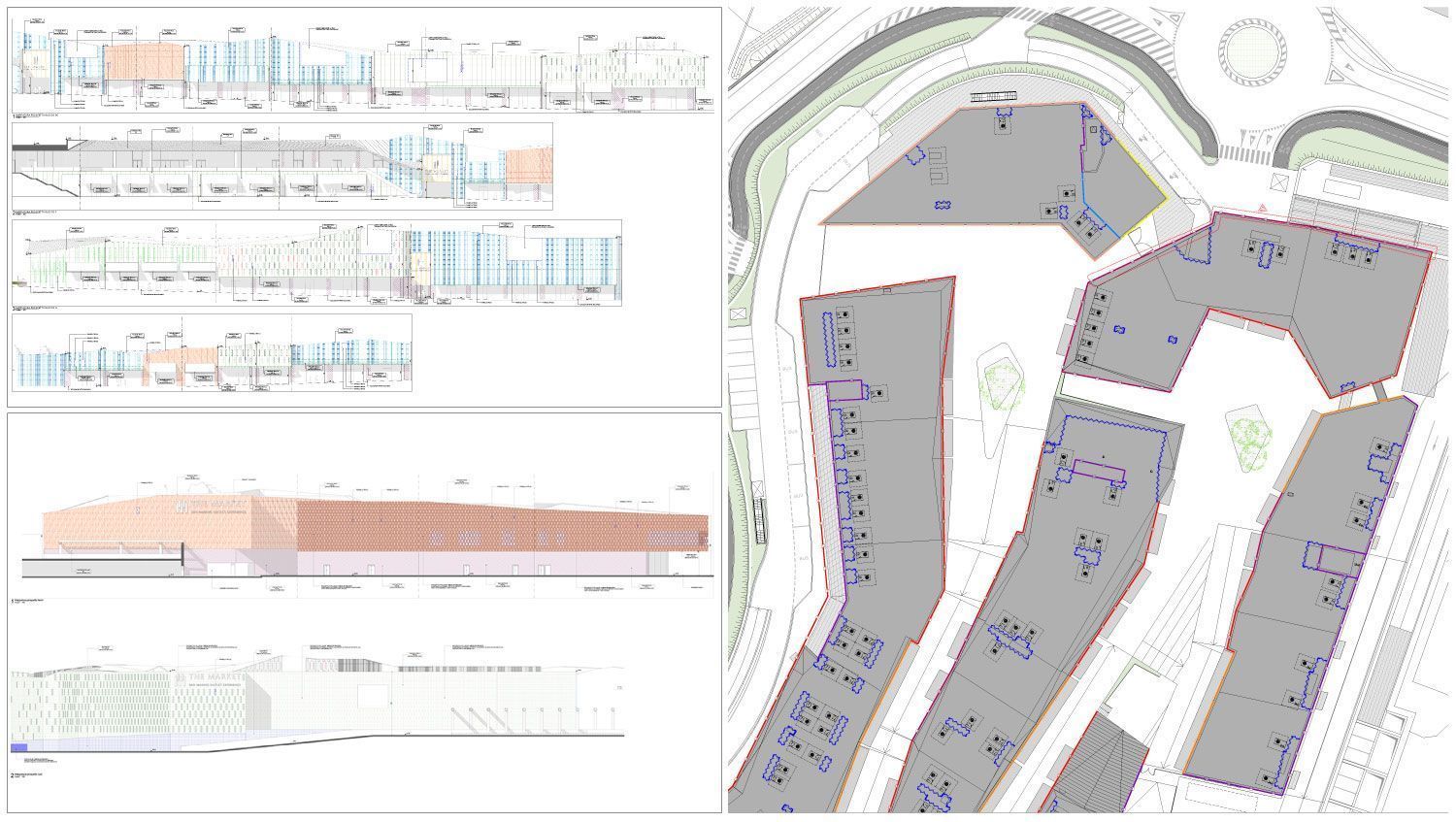

Executive Design

Architonic Drawings - Production Drawings - Layout Drawings

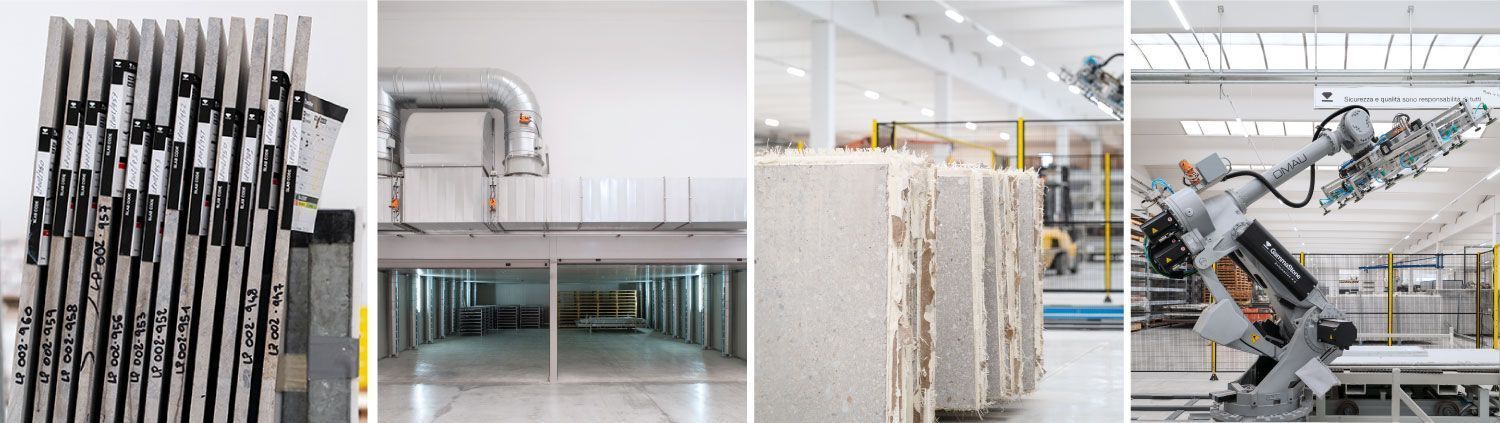

Procurement

Raw materials - Selection of blocks in quarry - Cutting blocks into slabs

Production

Panel plate production

Production Semi-finished products - Oven - Production of plated raw plates - Calibration and Honing panels

Panel machining

Cut-to-size - Panel machining with robot - Angle cutting

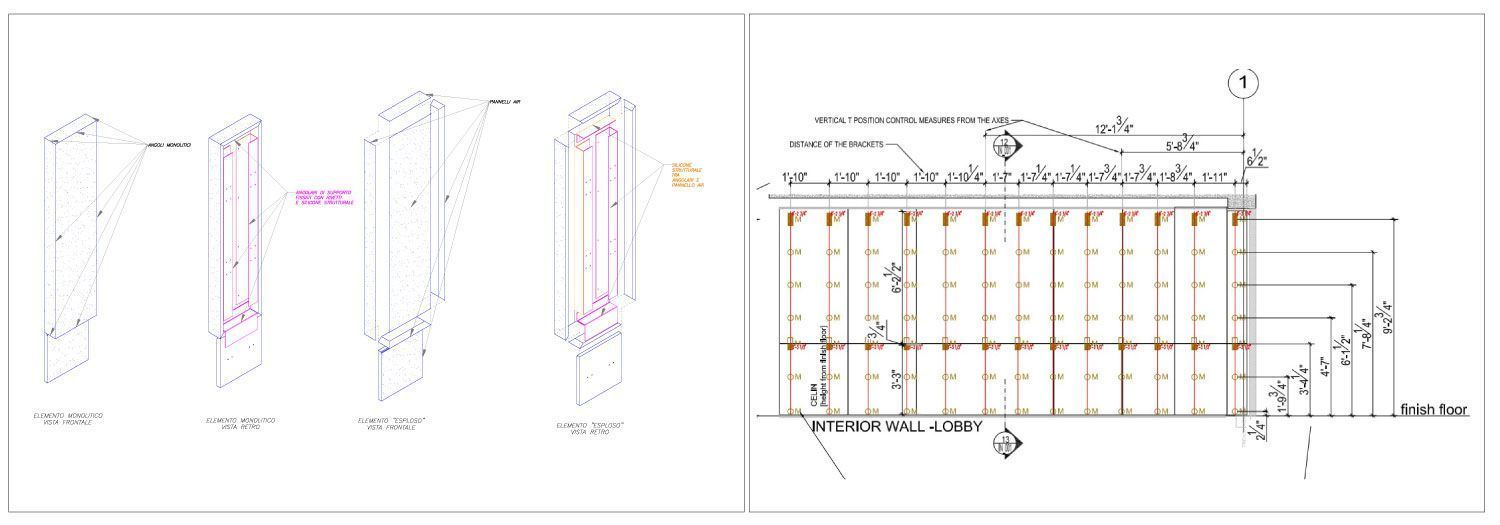

Assembly

Monolithic Elements Assembly - Structure Installation - Clip Installation

Final phase

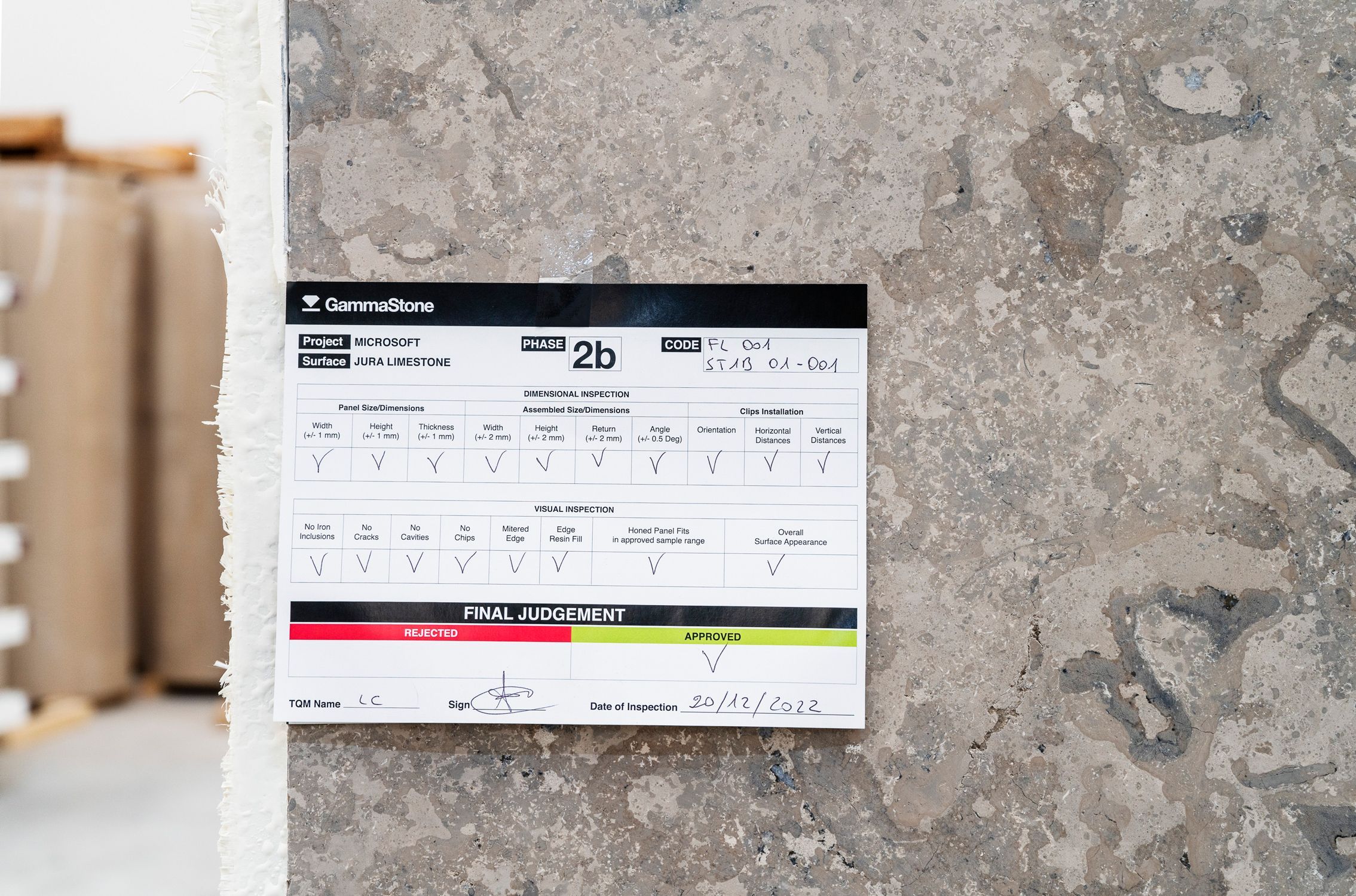

Quality Control

Final QC

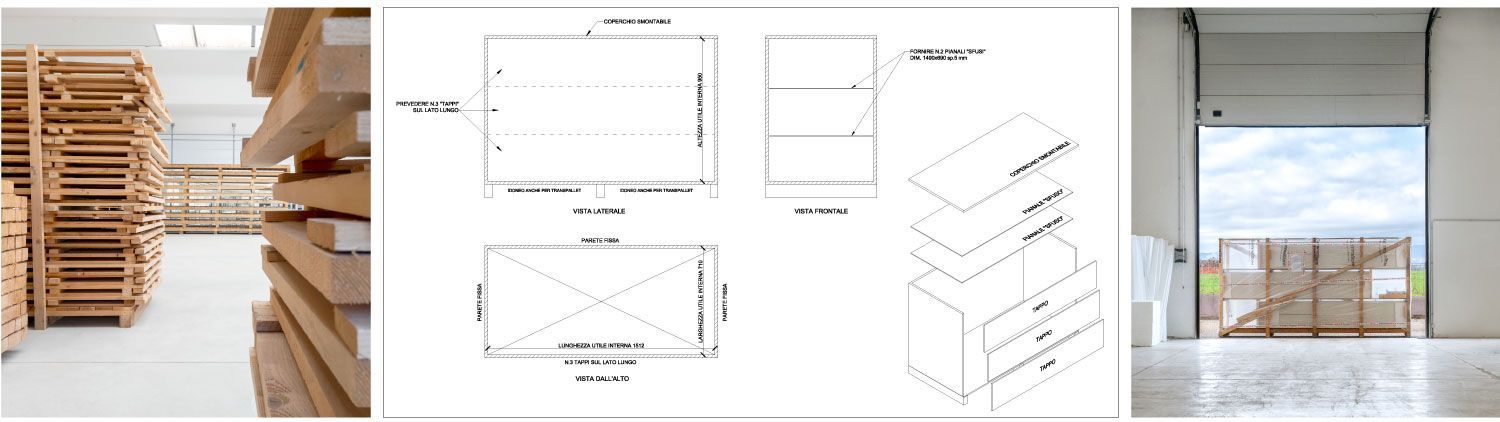

Shipping

Packaging - Loading - Shipping

Closure

Installation

Installation

Completion

Final Testing - Project Completion