Modelling and Construction Information

We are at the forefront of applying BIM software for building façade engineering, enabling our customers to meet the project's BIM requirements. GammaStone's BIM application includes the detection of interference between façade elements and the surrounding construction, and general coordination between the structure with other sectors. We can also translate the details of the 3D façade system into manufacturing drawings of parts for production applications. We are adding GammaStone panel BIM objects/models to “cloud” BIM libraries and portals.

Stone Procurement

In addition to design, engineering and drafting consultancy for natural stone cladding projects, GammaStone offers complete stone sourcing services to architects and designers. We can identify economic, aesthetically and structurally sound material options and assist them in sourcing for architectural stone cladding applications.

• Search for and procure samples of natural stone from quarries around the world

• Evaluate the capabilities of the stone quarry and the manufacturer

• Develop economical prices for material acquisition and installation

of the cladding

• Establish a protocol for observation and pre-construction testing on stone

• Suggest stone material alternatives and technical detail options to improve value

• Observe the plate mockup standing and coordinate the record samples

• Coordinate large-scale visual prefabrication mockup at the stone fabrication plant

• Review contractual drawings, executive drawings and calculations

• Perform peer reviews of subcontractor design

• Observe the manufacture of materials for aesthetic and structural compliance

• Establish a production stone testing protocol and observe testing

• Review and comment on the field machining model

• Observe the installation of the stone cladding on the project site for compliance with design requirements.

Design

Designing a cladding system for a new building whether it is ventilated, micro-ventilated etc. is a complex procedure.Requires industrial design criteria that must be considered and defined before starting construction to avoid substantial and/or unforeseen changes during the various phases of the production process.

GammaStone can develop projects considering the different modules of the façade: architectural elements made without joints or façade components such as openings, string-courses or other non-modular elements. These elements are usually necessary during the renovation work.

The GammaStone technical office elaborates customised executive drawings to optimise the number of cuts on the plate, to obtain an impeccable aesthetics in the matching of formats avoiding waste of precious materials.GammaStone's technical office is made up of a team of architects

and engineers aimed at the development of projects following

all phases of the design process:

• Recognition of projects and/or architectural concept for the

building cladding system

• Feasibility assessment

• Identification of the materials of the perimeter wall to be coated

• Definition of the structural plan and its general calculations

• Realisation of the executive drawings of the projects

GammaStone offers the following integrated design services:

• Development of the construction design

• Development of records

• Mounting table

• Sizing of panels

• Calculations of the joints

• Optimisation of scraps according to the size of the slabs

• BOM processing

• Static analysis

• Packaging bill processing

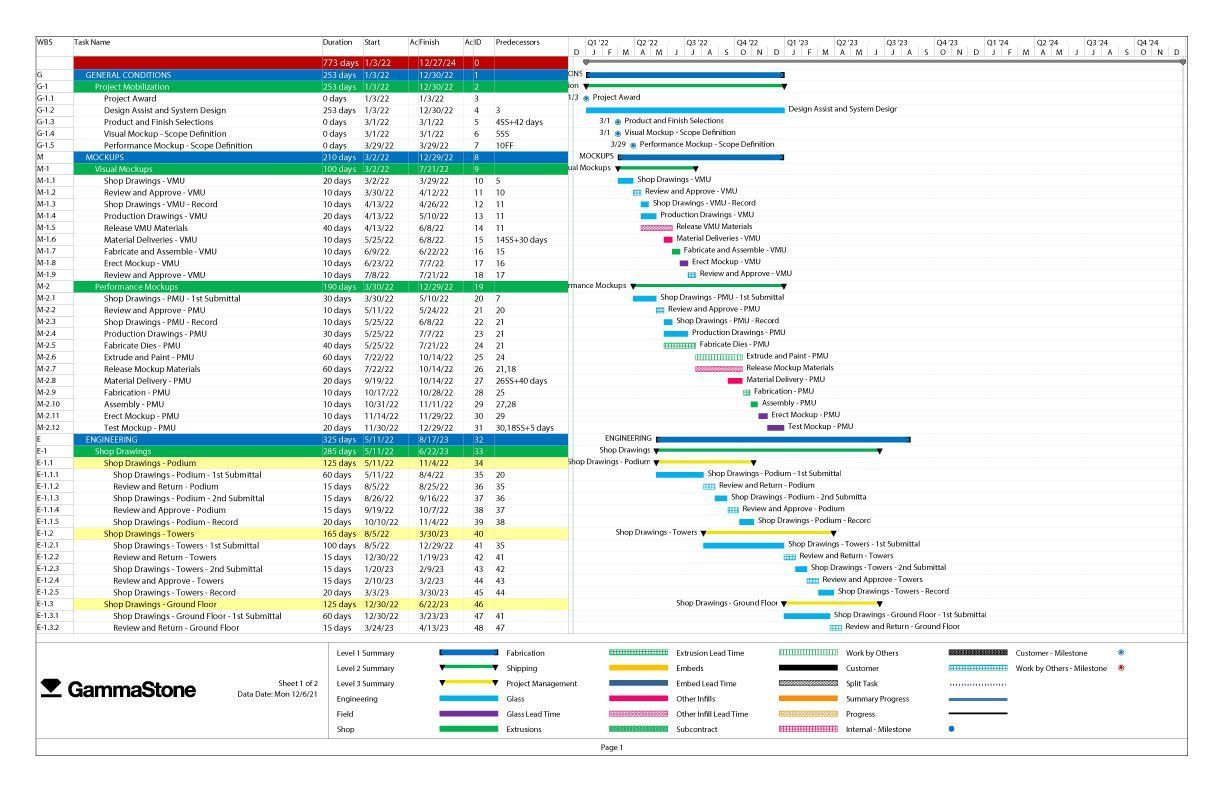

Project management

GammaStone is also known for its excellent project management service. The company can manage every step of the production process, from design to final product delivery, efficiently and professionally. Thanks to attention to detail and customer care, GammaStone can meet the varying needs guaranteeing a personalised and high-quality service. Thanks to our experience, the quality of the products and this high-level project management service, we can offer customised and innovative solutions for every type of architectural cladding project, both for the residential and commercial sector.

Over time we have shown that we have an excellent ability to manage the schedules of architectural cladding projects. Thanks to a highly qualified and professional team, able to plan and coordinate each phase of the project, we ensure that all deadlines are met in a timely manner and that the project is completed within the established deadlines. In addition, we also take care of the most complex and challenging projects, ensuring a high level of precision in the planning and execution of the work. Our services'reliability is one of our main strengths.

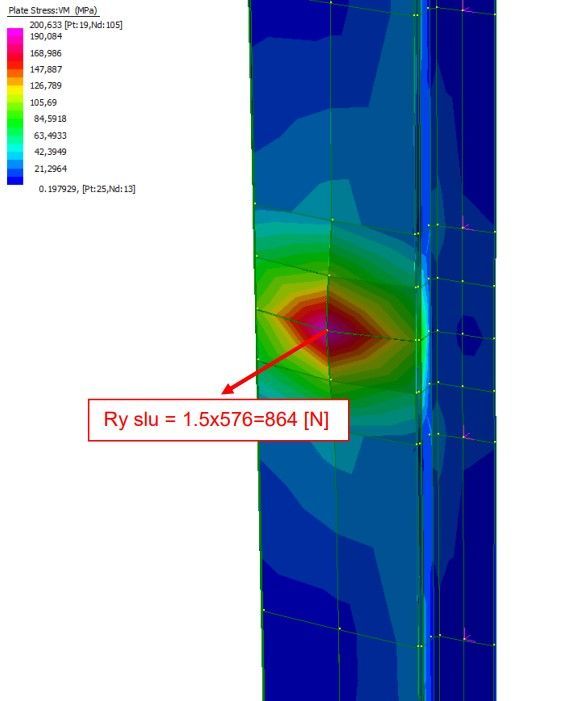

Static and Thermal Analysis

Care in the static calculation of each individual panel is a fundamental aspect, to guarantee maximum reliability and structural safety.GammaStone uses advanced static analysis techniques to verify the strength of each panel, taking into account the various stresses to which it could be subjected during the life of the product. Thanks to these accurate calculations, we can produce highly resistant and safe panels, able to meet the needs of architectural cladding projects of all types and sizes. In addition, the fact that each panel is calculated statically means that we can provide customers with a higher quality and safety guarantee than other manufacturers of architectural cladding panels. Our products are ideal for projects that require reliable and resistant materials over time, such as the external cladding of buildings, façades and internal partition walls.

Static calculations consider a uniformly distributed unit load (weight, pressure and depression). The loads used for the different sizing procedures are evaluated using the principle of overlap (linear-elastic calculation).

The design procedures of all the elements of the façade comply with the following combinations considering the most significant stresses (wind load, own weight, load of ice formations, seismic load).

Note: The design of the façade elements will be provided for the combination of the most relevant load. Details of the design of the shelves, the fixing of the bracket to the base material and the fixing of the profile to the bracket are given in separate documents (system static).

Our panels also guarantee excellent thermal performance, thanks to the use of advanced thermal analysis techniques for calculating the thermal resistance of each panel. This feature makes products ideal for architectural cladding projects that require a high level of thermal insulation, such as for residential or commercial buildings. The use of high-quality materials and the attention to precision in the production of the panels allows us to offer a product that guarantees high energy efficiency, helping to maintain a constant temperature inside the building and thus reducing the energy consumption necessary for heating or cooling the rooms. In addition, the use of panels with a good thermal performance allows to reduce heat dispersion from the building, improving the internal comfort of the rooms and guaranteeing long-term energy savings. In this way, our products not only offer a high level of structural performance and safety, but also a significant benefit in terms of energy efficiency and environmental sustainability.Our panels are characterised by an inner core of insulating material, which performs a thermal barrier function against changes in external temperature. Thanks to this innovative design, the panels offer high thermal resistance. Therefore they are ideal for architectural cladding projects that require a high level of energy efficiency and thermal comfort, such as for residential, commercial, hospital and school buildings.

Gammastone has developed an exceptional working relationship with numerous architectural firms around the world. These regularly involve us at the beginning of the design: collaboration from the beginning of the design process helps to eliminate problems before they become construction problems.

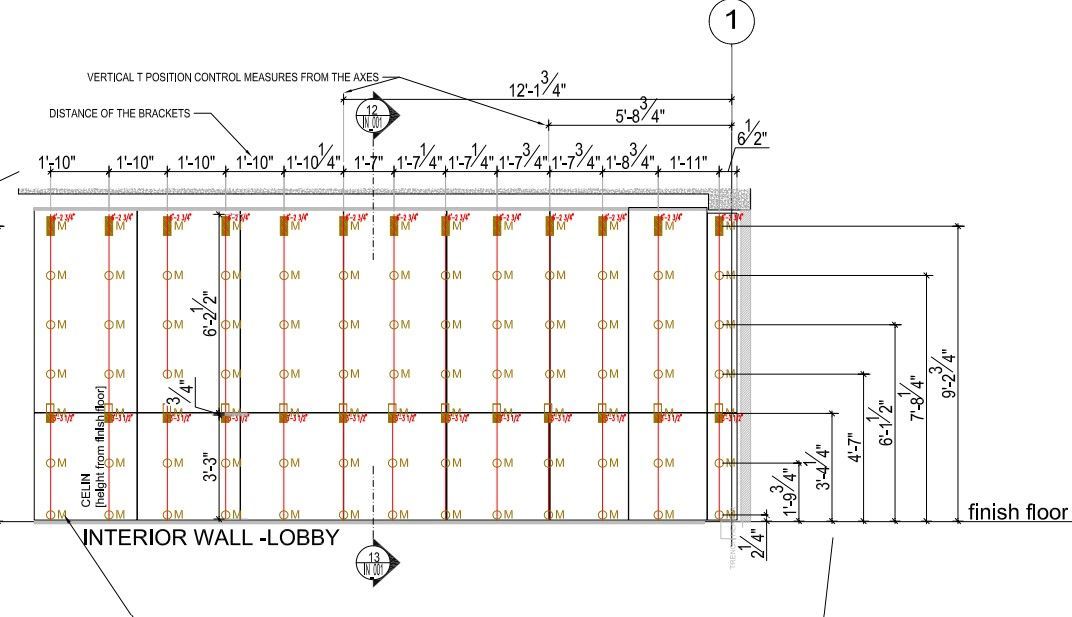

Layout drawings

Our technical department develops the drawings for each project related to the laying plans or laying tables; starting from the design, through production and packaging. The different phases meet the same criteria and follow the priorities until the final assembly phase. Each piece is accompanied by the technical data sheet and the identification codes associated with the schedule of the entire project.

Installation

The installation of GammaStone façades is extremely simple and safe: one of the services we are most proud of. Thanks to the collaboration of leading companies in the production of anchoring systems that are already known and tested, our solution allows you to reduce time and costs. The installer is equipped with all the specific indications for the activity on site: thus the work is carried out in a timely and fast manner. Thanks also to the extremely low weight of the panels, the installation is easier than other ventilated façade solutions.